Introduction to Torque Multipliers

Introduction to Torque Multipliers

What is a torque multiplier?

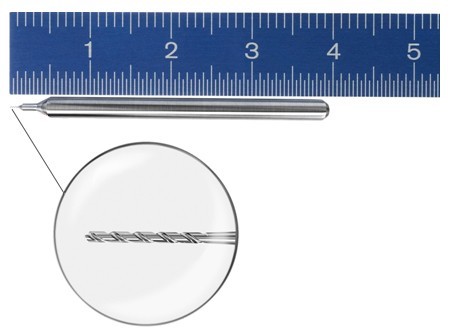

Torque multiplier, also known as torque amplifier, gear reducer, power booster, etc., is a device that can increase torque. Since the output power does not exceed the input power, the output revolutions are lower than the input revolutions. (Torque * speed = power) Torque multipliers generally achieve torque multiplication through planetary gears, generally 5 times to 125 times, and the maximum output torque can reach about 50,000 Nm.

The torque multiplier is composed of a circle or planetary gears combined in different combination levels to drive the gears to rotate and output. The torque magnification factor of each level gear is 5. The conventional ratios are: 1:4.2, 1:16, 1:21.5, 1:25 and more. In a planetary gear system, torque is input and output via the sun gear. The rotation is driven by three or four planetary gears combined with the sun gear. Circumferential gears within the multiplier housing engage the surrounding inner planetary gears, but in the opposite direction of rotation relative to the rotation of the inner planetary gears. The reaction arm can prevent the rotation of the casing integrated with the circumferential gear, and make the planetary gear rotate around the sun gear to drive the drive square to rotate, thereby outputting torque.

It is a torque multiplier for the disassembly and assembly of fasteners, including an input end turntable, an output end turntable, a gear shaft, a planetary gear reduction mechanism, a reversing mechanism and a fixed frame. The planetary gear reduction mechanism includes a central wheel and several planetary gears, bearings and shafts. The gear shaft is installed in the center of the input turntable, and the reversing mechanism is installed on one side of the gear shaft. The planetary gear reduction mechanism is installed between the input end turntable and the output end turntable. The utility model is labor-saving and convenient, can be operated in a narrow space, has high work efficiency, and can be electric or manual.

Precautions for the use of torque multipliers:

1. Pay attention to the maximum output torque and magnification of the torque multiplier, and do not use overload, otherwise, it will be damaged;

2. When tightening and removing bolts, the torque wrench should be applied evenly. During the tightening and dismantling process, pay attention to the fact that the reaction arm wrench must be firmly fixed;

3. The torque multiplier is a precision appliance, and it should not be hit strongly or damp, otherwise it will also be damaged.

Maintenance requirements for the torque multiplier:

(1) Regularly replace the internal lubricating oil of the multiplier every year;

(2) Do not damage the appearance of the multiplier. When the anti-rebound safety device carries out the nut locking operation, the high rate gearbox (1:25 or higher) will produce a certain amount of recoil force. When the input device is released (or loosened), it will produce a rebound action, and the rebound direction is opposite to the operation direction.

The function of the anti-rebound safety device is that when the rebound force is generated, the anti-rebound ratchet device will maintain the elastic force without releasing.

Note: before locking the nut, it is necessary to confirm that the anti-rebound safety device is suitable for the locking operation direction of the nut.

The anti-rebound safety device has the following advantages:

1. If it is accidentally released, the torque input device will not suddenly rebound in the direction of operation to ensure the safety of the operator;

2. If there is no anti-rebound safety device, it is often necessary to confirm that there are no obstacles in the 360-degree rotation of the torque device because obstacles will make the multiplier unusable;

3. The anti-rebound safety device and the reaction force point of the reaction force arm of the multiplier can make the multiplier tighten the nut. Even if the torque multiplier is used upside down, it can also support the weight of the torque multiplier itself.

How to remove and install bolts that require high torque?

To solve the problems mentioned above, first of all, we should fully understand the various characteristics of bolts (internal factors), the environment (external factors) and so on. The various characteristics of the bolt need to be learned from the technical personnel of the bolt manufacturer, including the hardness, strength grade, yield point, elongation after fracture, etc. of the bolt, which should comply with international standards ISO898-1 ISO898-2 ISO6157-1 ISO6157-2. According to the torque experiment, we recommend that the tightening torque of the bolt is in N.m (Newton. Meter). The torque values we mention here are calculated based on a friction coefficient of 0.14 (new bolts \ no lubrication \ no post-treatment). External factors that affect the torque of bolts generally include: temperature, lubrication, corrosion, bolt gaskets, whether reinforcing glue is used, etc.

TorcStark New ED Series Torque Multipliers

Advantages of ED Series Torque Multipliers

Lightweight aluminum body;

Equipped with a reaction arm;

Torque value up to 10000Nm;

Single-stage planetary gear unit with torque values up to 2800Nm;

Two-stage planetary gear unit with torque values up to 10,000Nm.

If you want to buy a torque multiplier or are looking for a reliable torque multiplier manufacturer, please contact us.