How to Use The Torque Multiplier?

How to Use The Torque Multiplier?

The torque multiplier is an indispensable tool in the production process, so the operator must know how to use the torque multiplier correctly. Torque multiplier is a must-have tool in many heavy industries, and it provides a safer and more precise tightening process, ensuring that fasteners are neither too tight nor too loose. They reduce the need for future repairs and readjustments, thereby increasing worker efficiency and productivity.

TorcStark will show you how to use the torque multiplier in detail

How the torque multiplier works:

The torque multiplier uses a planetary gear train with one or more stages. Each stage of gearing increases the applied torque by a factor of 5. In a planetary gear design, the wrench applies torque to the input gear or sun gear. This action rotates three or four planet gears whose teeth mesh with the sun gear. The housing of the multiplier (the ring gear or ring gear) also meshes with the gear teeth and usually rotates in the opposite direction to the sun gear. The reaction arm is there to prevent the casing from rotating, which would cause the planet gears to rotate around the sun gear. The planetary gear is fixed in the planet carrier, and the planet carrier also fixes the output side drive. Therefore, as the planet gears orbit the sun gear, the planet carrier and the square drive rotate. So without a reaction arm to keep the housing stationary, the torque multiplier will not apply torque.

Detailed steps to use the torque multiplier:

Always read the instructions before use and be sure to maintain the tool according to the advice provided.

Refer to the Manual or Specification for the required torque.

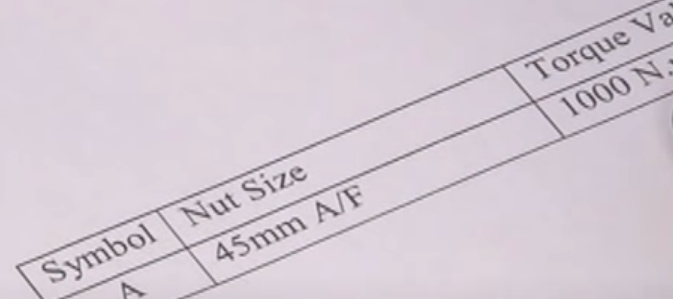

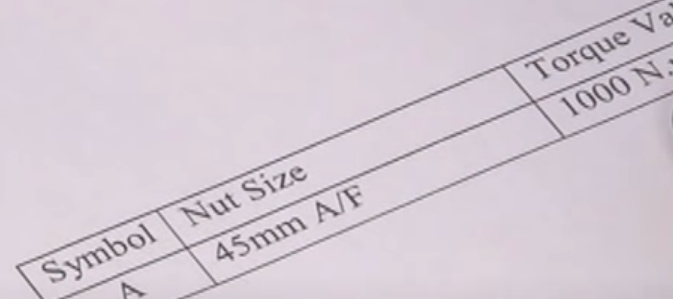

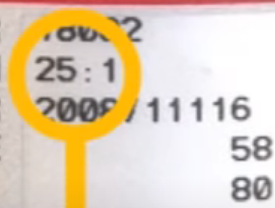

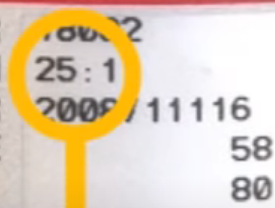

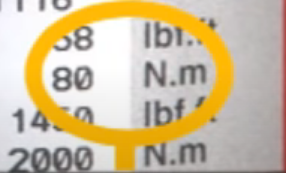

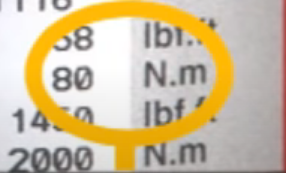

Set the torque wrench to 1/25 the desired torque

Never exceed the maximum input torque

Assemble socket, ‘O’ ring and retaining pin

Do not use an extra long extension or socket

Do not use universal joints

Place multiplier on the fastener

Check if the multiplier is rotating in the required direction

Check that the wrench is rotating in the required direction, and put it on the multiplier

Choose a suitable reaction point

Good reaction point

Poor reaction point

The result of the poor reaction point

Tighten until you hear a click

The multiplier is now locked on

Do not strike the anti wind-up ratchet

Release wind-up in the following sequence of operations

Replace the wrench

Load torque wrench

Reverse direction of anti wind-up ratchet

Ensure you release the wind-up in a safe and controlled manner

Notes when using the torque multiplier:

Read all instructions before use. Improper use can damage both tools.

Maintain the tool according to the recommendations provided.

Set the torque wrench to 1/25 the desired torque.

Check that the multiplier rotates in the desired direction.

Choose an appropriate reaction point.

Pay attention to the torque value of the matching wrench, and do not use overload.

Try to keep the wrench drive head, the multiplier and the locked object on the concentric axis.

Try to maintain the largest flat contact surface of the reaction arm with the resist.

Try to keep the reaction force at right angles to the reaction arm.

The reaction force point should be as far away as possible from the multiplier and within the safety triangle area.

To remove the multiplier, remove the wrench first, and do not hit it.

It is forbidden to use electric tools or pneumatic tools to drive the torque multiplier.

Summarize

The torque multiplier is relatively simple to use, but we need to pay attention to more details to prevent damage to the tool and personal injury. For example, finding a suitable reaction point for the reaction arm, and when removing the multiplier, the ratchet is rotated in the opposite direction to release the mainspring. TorcStark’s new ED series torque multiplier has a torque value of up to 10,000Nm, and the torque value of a single planetary gear is 2,800Nm. If you want to buy a torque multiplier or are looking for a reliable torque multiplier manufacturer, please contact us by mail. We have unparalleled competitiveness in terms of product quality and price.