Best Circular Saw Blade for Cutting MDF –

If you own a circular saw, then you already know that picking the right blade for the right material is really important to get the best cleanest cut. You will also likely know that circular saw come in different sizes, so not one blade fits all. I am going to explain what the best blades are to cut MDF boards. Medium Density Fibre (MDF) boards are used extensively in the UK. Being able to cut these quickly, and without chipping is an important job to get right. Let’s get started.

Just below, I have included a table of contents. If a particular section interests you, then just click on that and you can read that section. I would recommend reading all of the information though, as it will help you make the best decision.

What is MDF Exactly?

I believe that if you know what you are cutting, it makes mores sense to understand which blade type you use. MDF is the shortened name of Medium Density Fibreboard. This is an engineered man-made wood so it’s not a natural wood. It is made from wood fibres, resin, and wax, which are compressed together under high temperature and pressure. Wood fibres means using sawmill shavings, wood chips, or sawdust. The size and consistency of these fibres is what ends up being the density and quality of the MDF.

The wood fibres are then blended with a resin binder and act as a glue to hold the fibres together. Depending on the manufacturer they may also add wax, paraffin, or dyes. The mixture is then dried to reduce moisture content.

It is then placed onto a conveyor belt where it gets turned into a layer of of uniform thickness. This mat is then placed between two heated platens in a hydraulic press. Extreme pressure and a high temperature are applied, which makes the resin cure and bond the fibres together, forming a solid panel.

The panels are cooled down gradually. The edges may be trimmed, and the surface can be sanded to achieve a smooth finish. Depending on the intended use, the MDF panels may get additional treatments or coatings to improve their properties, such as moisture resistance or improved surface texture.

The final MDF panels are uniform in density and have a smooth surface that is free from knots, grain patterns, and other natural defects found in traditional wood. They are versatile and commonly used in furniture production, cabinetry, moulding, and other applications in construction and manufacturing due to their consistent quality and ease of shaping.

Sizes, Thicknesses & Uses

When buying a circular saw blade for MDF, you need to think about the size of your circular saw, and most importantly the thickness of the MDF sheet. This was something I initially didn’t give much thought to, and that was a big mistake. It is really important to understand.

Thickness

MDF Sheets come in the following thicknesses in the UK:

|

Thickness (mm) |

Uses |

|---|---|

|

2.5 |

Known as thin MDF and is used for back panels of furniture, veneering, or in applications where a thinner material is required. |

|

6 &9 |

These thinner boards are suitable for interior projects such as shelving, cabinet backs, and decorative paneling. |

|

12 |

Used for a wide range of applications, including furniture construction, cabinet making, built-in wardrobes, and general carpentry projects. |

|

15 |

Similar to 12mm, this thickness is also used in furniture making, interior fittings, and various carpentry applications. |

|

18 |

One of the most commonly used thicknesses for MDF boards, particularly for kitchen cabinets, shelves, tables, and other furniture pieces. |

|

22 and above |

Thicker MDF boards are used for heavier-duty applications such as constructing certain types of furniture, structural elements, or when extra strength and durability are required. |

18mm is about 0.7″ and is without doubt the most popular size used in the UK. So any circular saw blade needs to be able to cut through that thickness. Some small circular saws (mini) will just not be able to do that.

Board Sizes

In the UK, MDF boards are available in various lengths and widths. The standard size is 2440mm x 1220mm (8ft x 4ft). However, different sizes might be available depending on the supplier or manufacturer.

- Lengths can vary from as short as 1800mm (6ft) to as long as 3050mm (10ft) or even longer for special-order or custom-cut boards.

- Widths, apart from the standard 1220mm (4ft), might also be available in smaller widths like 600mm (2ft) or wider widths like 1830mm (6ft) or more for specific applications or based on supplier availability.

- Always check with your local supplier or retailer for the specific lengths and widths they have in stock, as they may differ among different suppliers or manufacturers.

- Some suppliers might offer cut-to-size services, allowing you to obtain MDF boards in custom lengths and widths to suit your specific project needs.

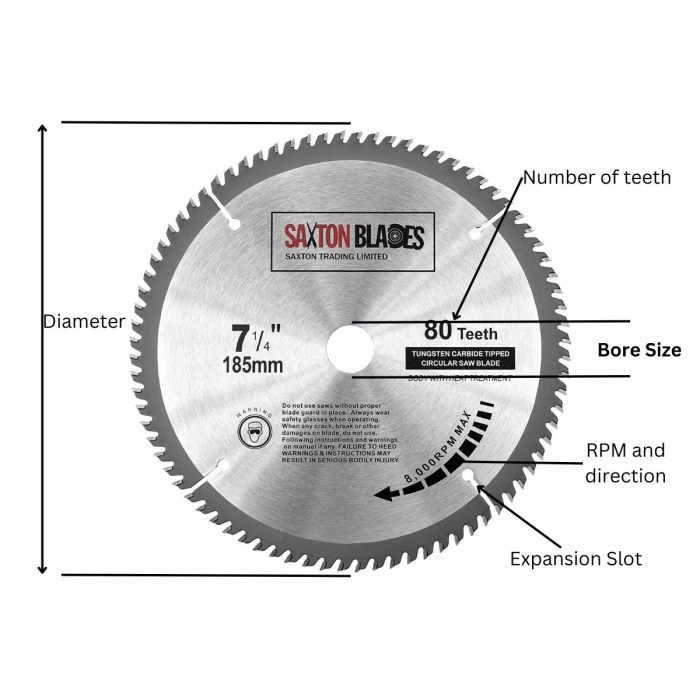

Picking the Right Blade

Here are my tips, based on my experience, to help you select the right circular saw blade for cutting MDF:

- I have found that Tungsten carbide-tipped (TCT) blades are the best for cutting MDF as they are durable and maintain their sharpness.

- Blades with high tooth counts (usually 60 to 100 teeth) produce smoother finishes with minimal splintering on the surface of the MDF.

- Blades with alternate top bevel (ATB) or triple-chip grind (TCG) tooth configurations work well for cutting MDF.

- Consider a blade with a negative hook angle to reduce aggressive or overly fast cutting, which can lead to splintering or tear-out on the MDF surface.

- Make sure that the blade size matches the specifications of your circular saw. Common circular saw blade diameters range from 155mm to 255mm (6.5 inches to 10 inches), but the specific size depends on your saw’s capacity.

- Buy a reputable brand known for producing high-quality saw blades. Quality blades tend to have better carbide tips and are engineered for cleaner cuts with reduced tear-out.

- Some blades special coatings like non-stick coatings or anti-friction coatings. While not strictly necessary, these coatings can help reduce heat buildup and improve the blade’s longevity.

Purpose and Intended Cuts:

Think about the specific project or cuts that you intend to make in the MDF. For straight crosscuts or rip cuts, different blades might be optimal. If you need more general use, a general-purpose blade may do the job nicely.

Test the blade on a scrap piece of MDF before making your actual cuts as that can help ensure you achieve the desired results.

My Blade Choices

Over the years I have cut a lot of MDF boards with different sizes of circular saw. Here are my preferred choices:

Best 165mm (6.5″) blade

Click to see a larger image

Saxton TCT Circular Fine Cutting Wood Saw Blade.

- Blade Size: 165mm x 20mm bore with 60 teeth (comes with a 16mm reduction ring).

- It has a 1.5mm kerf and an ATB tooth design.

- The blade works with Bosch, Dewalt, Makita, Ryobi and most circular saw brands.

- They cost around £12 – Check availability at Amazon UK

Best 185mm (7.25″) blade

Sabrecut FineLine Thin Blade.

Click to see a larger image

- Blade Size:185mm x 30mm bore with 80 tooth. (Comes with 25.4mm, 20mm & 16mm reduction rings)

- It has a 2.4mm kerf and an ATB tooth design.

- The blade works with Bosch, Dewalt, Festool, Hitachi, Makita, Milwaukee and most circular saw brands.

- They cost around £18 Check availability at Amazon UK

Best 190mm (7.5″) blade

Click to see larger image

Saxton TCT19080T TCT Circular Wood Saw Blade.

- Blade Size:195mm x 30mm bore with 80 tooth. (Comes with 16, 20 and 25mm reduction rings)

- It has a 2.4mm kerf and an ATB tooth design.

- The blade works with Dewalt, Bosch, Makita, Ryobi and most circular saw brands.

- These cost around £12. Check Availability at Amazon UK.

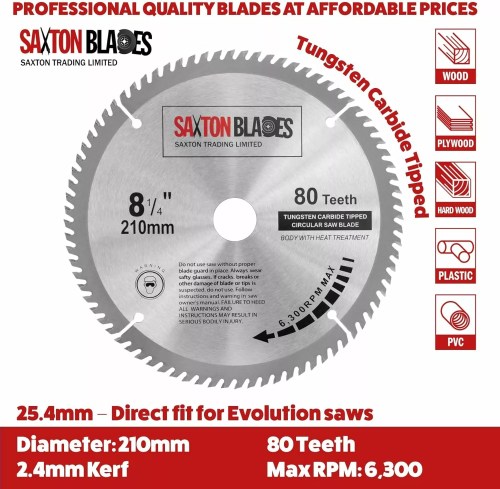

Best 210mm (8.25″) blade

Click to see a larger image

Saxton TCT21080T254B Circular Wood Saw Blade.

- Blade Size:210mm x 25.4mm bore with 80 tooth.

- It has a 2.4mm kerf and an ATB tooth design.

- The blade works with Evolution saws and most circular saw brands.

- These cost around £16. Check Availability at Amazon UK.

Best 235mm (9.25″) blade.

Edit your caption text here

Saxton TCT23580T TCT Circular Wood Saw Blade

- Blade Size:235mm x 30mm bore with 80 tooth. (Comes with 25mm, 20mm & 16mm reduction rings)

- It has a 2.6mm kerf and an ATB tooth design.

- The blade works with Dewalt, Bosch, Makita, Ryobi and most circular saw brands.

- These cost around £17. Check Availability at Amazon UK.

Best 250mm (9.8″) blade

Saxton TCT19080T TCT Circular Wood Saw Blade.

- Blade Size:195mm x 30mm bore with 80 tooth. (Comes with 25.4mm, 20mm & 16mm reduction rings)

- It has a 2.4mm kerf and an ATB tooth design.

- The blade works with Bosch, Dewalt, Festool, Hitachi, Makita, Milwaukee and most circular saw brands.

- These cost around £18. Check Availability at Amazon UK.

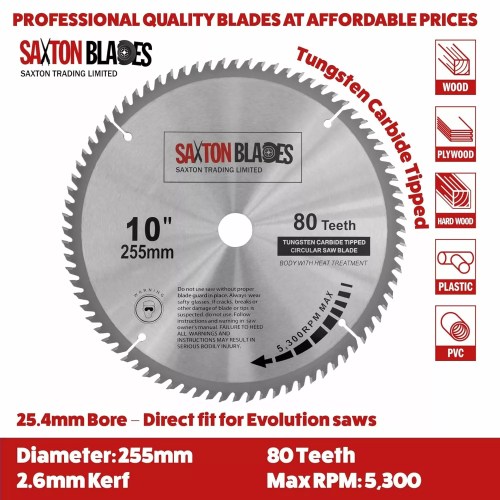

Best 255mm (10″) blade

Click to see a larger image

Saxton TCT25580T254B Circular Wood Saw Blade.

- Blade Size:255mm x 25.4mm bore with 80 tooth.

- It has a 2.6mm kerf and an ATB tooth design.

- The blade works with Evolution and most circular saw brands.

- These cost around £19. Check Availability at Amazon UK.

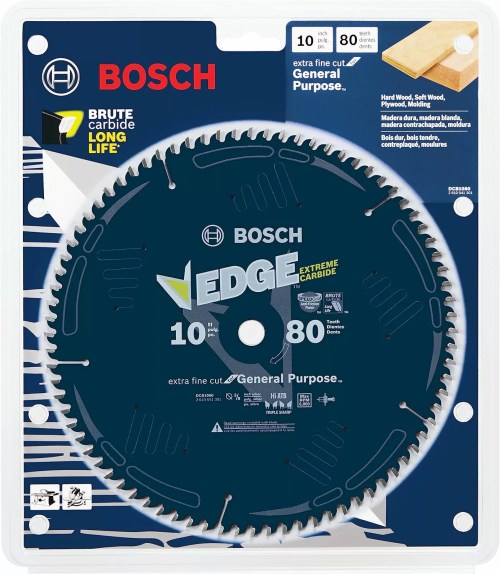

Best Veneer MDF blade

Click to see a larger image

Bosch 2608644128 Circular Saw Blade.

- Blade Size: Available in various sizes

- Kerf sizes will vary slightly

- The blade works with Bosch, and most circular saw brands.

- These cost around £40. Check Availability at Amazon UK.

Cutting Advice

The usual general advice applies such as wearing safety glasses when doing any cutting. With relation to cutting MDF there are a few really important things to remember for your safety:

- Cutting MDF creates a lot of fine dust particles and it’s worth remember that these will contain resins and wood fibres. Inhaling this dust can lead to respiratory issues, eye irritation, and skin allergies. Make sure to always wear a face mask, when cutting MDF.

- Cutting MDF also generates heat. In most cases I have never had any real issues as I use really sharp blades. I do know people who have used blunt blades and those can become hot enough to ignite the material. It was prolonged use, but nevertheless, it can happen

I trust you have found this information useful. Always check the size of your saw and the bore size before picking a blade.