Jigsaw Blade Buyers Guide UK –

Thanks for taking your time to read our jigsaw blade buyers guide UK. The type of jigsaw blade that you need to buy will depend on the type of jigsaw that you own, or plan on buying. Your choice of blade should also be dictated by the type of material you want to cut. In most cases, that will be the various types of wood, but it could also include plastic, light metal, tiles, ceramic etc.

In this article we explain pretty much everything there is to know about jigsaw blades and which are the best ones to consider buying. However, let’s get started with some important basic information.

Understanding Jigsaw Blades – The Basics

There are four main considerations to bear in mind when picking a jigsaw:

- Type of Blade Fitting – T-shank vs U-Shank

- What type of material you are cutting? – As mentioned wood, plastic, aluminium etc

- The type of cut that you want to achieve? – coarse cut, fine cut, curve cut, etc

- The depth of cut that you require? – a very important and often neglected measurement

- How much you are prepared to spend on a jigsaw blade? – the amount you spend should be based on how often you plan on using the jigsaw and what you are using it for.

We have explained each of these in more detail below.

What is the Difference Between T-Shank and U-Shank Blades?

T-shank blade

U- shank blade

This should be your most important consideration, when it comes to buying blades for your jigsaw. The way the blade is inserted into the saw can be done in one of two methods as explained below:

- U-Shank – (sometimes referred to as universal) You will find this style on older models of jigsaw. The U-shaped part is at the top of the blade, and it slides into the jigsaw, and is then clamped in place using a small screw or a small Allen style screw. Although this system works, it made the process of changing a blade slow and very fiddly. If you ever lost the small screw, then it was a huge pain to get a replacement.

- T-Shank – (also referred to as lug by some manufacturers like Bosch or SDS by other brands) – These T-shaped blades now dominate the UK market, and are designed to push in to your jigsaw and lock into place, without the need for and tools or screws. They essentially slide into the jigsaw and are released using a quick release clamp. That makes changing a blade very fast. It is described by manufacturers as a tool less blade change. (In the UK market 90% of all current jigsaw makes and models use these)

A huge benefit of purchasing T-shank blades is that they will give you access to a much wider range of jigsaw blades for cutting different materials. In reality, most people will only ever use a jigsaw blade for cutting wood. However, if you also plan on using your jigsaw to cut plastic or thin metal, then having a wider selection of blade types is very important.

Just be aware that older models of jigsaws will use U-shaped blades, so be careful when buying new blades.

Some new models of jigsaws will take both types of blades so worth noting that when you are buying a new jigsaw.

It is also worth noting that the Makita brand use specific fittings and other tool brands are also considering doing the same.

What Material Are You Cutting with a Jigsaw Blade?

Most users will be using their jigsaw to cut wood. However jigsaws can be used to cut plastic and thinner metals such as aluminium sheet. The only thing you need to change is the type of blade that you are using.

When it comes to buying a jigsaw blade for specific materials, there are 4 types of blade available.

- Jigsaw blades for wood – these are blades just for cutting wood and there are lots of choices. These are usually made from High Carbon Steel (HCS)

- Jigsaw blades for metal – these are blades just for cutting metal and there are a number of choices. These are usually made from High Speed Steel (HSS)

- Jigsaw blades for wood and metal – also known as multi-purpose

- Jigsaw blades for specialty cutting – These are also known as multi-purpose blades for cutting foam layers, felt, leather, ceramic, tiles, glass, stone etc.

What Type of Cut do you want to achieve?

This is the main area that users get wrong when buying a jigsaw blade, and it is one of the most important to understand. The key to deciding which blade to buy depends if you are happy enough with a rough finish, of if you want a nice fine smooth finish.

We think it is better to explain this using a couple of practical examples.

If you are cutting out a shaped hole in a worktop to cater for something like a sink, then in reality, the hole cutout doesn’t need to have a neat fine finish. After all, when the sink is installed you will not see the actual cutout.

On the other hand if you cutting the edge of a shelf, then you will want a nice smooth finish. The question is how is this finish determined by the type of blade you buy.

Teeth Per Inch

Here is a very good rule of thumb. The more teeth per inch on a blade the finer and neater the cut will be. Most standard jigsaw blades come with 6-8 teeth per inch (6-8 tpi). This gives a good enough cut, but in some materials that can actually be quite rough. This is especially true for wood such as plywood.

If you want a finer finish then a blade with 10 tpi will be a much better choice. Woods such as veneers and laminates will need a much finer blade and cut and 20-30 tpi in this case would be the ideal choice.

Just be aware though that a 6 tpi blade will cut much faster than a 10 tpi, or a 20 tpi blade, so you will be sacrificing a little time.

Different Types of Jigsaw Blade Teeth

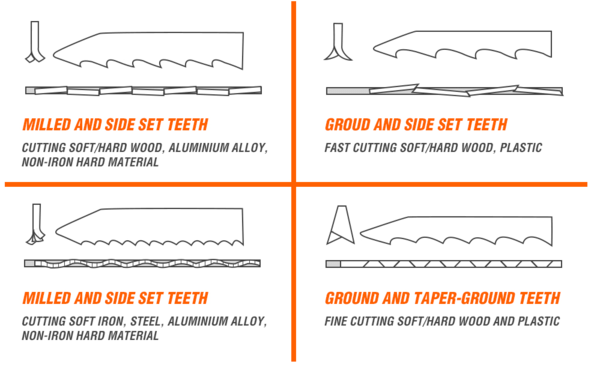

The image above shows the different methods of setting teeth on a jigsaw blade. There are again two types:

- Milled Teeth – this type of setting on the teeth helps cut faster and reduce the wear and tear on a blade and means they will last a great deal longer

- Ground Teeth – this type of setting produces a much better finish, but they cut slower and they can get very hot.

Unless you are doing really fine work, don’t get hung up on the manufacturing process. Most blades will have milled teeth and they work perfectly well.

What are Jigsaw blades nade of?

Jigsaw blades are made from different types of metal and we have listed these below. It is worth noting that some manufacturers may use combinations of the metals shown below to make their blades.

- Bimetal – These are a combination of high carbon steel and high speed steel and can cut wood, laminates and some metals. These are durable blades with good flexibility, and although slightly more expensive, tend to last long and seldom break.

- High Carbon Steel (HCS) – suitable for cutting wood and plastic and good for shape cutting or scrolling. These blades are pretty flexible and will only break if you really push too hard

- High Speed Steel (HSS) – suitable for cutting non ferrous metals (aluminium, nickel, tin, brass silver, zinc)and acrylics. These blades are very rigid so tend to break easier if you put too much pressure on them.

- Tungsten Carbide – These are for tougher rougher jobs like cutting through wood with nails in it

- Tungsten Carbide Grit- the really heavy duty jigsaw blade for cutting glass, bricks, tiles and concrete

Sawing Speed

This is determined in a few ways. The main speed is strokes per minute. That is the number of times the blade moves up and down in a minute without bearing a load. (Not cutting anything) Most jigsaws have variable speeds.

On variable-speed jigsaws, use a slower speed for harder woods and materials, such as metal or fiberglass. Increase the speed for cutting softer woods and plywood.

Cutting Curves with a Jigsaw Blade

The blade that you make a straight cut with, can not be used to make curve cuts. To make curve cuts the easy way, you need to buy a slightly more flexible blade. That will then allow you to make accurate shaped designs.

What Depth of Cut do you want to achieve?

This is a consideration that is often neglected as well. We shall explain this below:

Overall Length

Most manufacturers show the overall length of the blade. Typically this will look something like 3.25″ It is not that important to know this, other than as a general indication of the length.

Working Length

A much more important consideration is the working length, which is in effect how deep the blade can cut. For something like a 3.25″ long blade, the actual working length is 2-5/16″ so a considerable difference.

This is because you lose the top of the blade as that includes the shank that pushes into the jigsaw.

The key take away from this is only ever look at the working length of a jigsaw blade as this is how deep the blade can actually cut.

Single Blades vs Jigsaw Blade Sets

Another question we are asked frequently should you buy a single jigsaw blade, or buy a set of jigsaw blades?

Our advice would be to buy a set especially if you are just getting started. Overall a set is always going to be much better value for money.

The only exception to that rule would be, if you are buying a specialist type blade for a one-off project. For example if you ere buying a 20 tpi blade to cut a laminate floor for your home, then it would be batter just to buy a couple of those type of blades, rather than just a general purpose set.

Jigsaw Blades for Specialist Cuts

Sometimes you may need to cut something unusual, and to do that there are a few jigsaw blades for those specialist applications:

- Flush Cut Blades – These allow you to cut right up to the edge of the foot plate (Be aware your jigsaw needs to be able to cater for these blades

- Diamond Grit Blades – These are available to deal with the tougher materials such as granite, slate and on glass

- Knife Edge Blades – these are mainly used for cutting foam sheets, leather and cork

- Reverse Tooth Blades – These are made to actually cut on the downstroke of the jigsaw. They are used for working with veneered woods such as laminates of veneer plywood.

Bosch Jigsaw Blades

The biggest selling jigsaws on the UK market are made by Bosch. This brand sells more than any other brand. They also make a wide range of jigsaw blades for their jigsaws. Many of these are compatible with other brands. They have quite a large range, and the blade you need to use will depend on the cutting task you plan to undertake.

What is the Best Jigsaw Blade for Cutting Laminate?

If you are cutting boards for a laminate floor, or indeed cutting a laminate worktop, then you will always want a very fine finish.

The Bosch T 101 BR blade is one of the best on the UK market for cutting any type or laminate flooring

That is because it cuts on the down stroke as it has reversed teeth.

This blade creates clean top surfaces with minimal splintering and leaves a very good finish.

It MUST be used without either an orbital setting or a pendulum setting on your jigsaw to get the very best results.

92% buyer satisfaction based on 300+ online buyer reviews

Jigsaw Blades FAQ

Jigsaw blades do not fit all jigsaws. In the UK market around 90% of all jigsaw blades being used are T-shank blades. These fit into your jigsaw without the use of tools. They simply push in and then lock into position. They are released by a quick release chuck or mechanism.

However, on some older models of jigsaws, or on some cheap newer models of jigsaws, they will use U-shaped blades. These blades are inserted into the jigsaw, and then you need to tighten the blade into a small clamp using a screws, most likely a screw with an Allen key type head.

It can be difficult to know which type of jigsaw blade you have. The reason for this is that manufacturers use different symbols on their blades to identify them. Most of them use a model number which is in effect not that much use. You can however look that model number up on the manufacturer’s website.

Some manufacturers will also type on to their blade the material it can cut. One other method is to count the number of teeth per inch as that will tell you what type of finish to expect.

The T-shank is the most popular type of blade, and them simply push in and lock. We have added this useful video here on how to fit the various types of blades into different model of jigsaws. You can view it by clicking here.

TPIs on a jigsaw blade stands for the number of teeth per inch of the blade. A standard jigsaw blade usually has 6 teeth per inch and will be referred to as 6 tpi. This is find for most cuts. However if you need a finer cut for something such as laminate flooring, then a blade with 10 tpi will be a better choice.

When users refer to a down cut on a jigsaw blade, they are usually referring to a reverse-tooth blade cut on the downstroke. These are a special blade used to cut the face of veneered laminate or plywood to leave a very smooth finish. The blade actually cuts on the downstroke, rather than on the up stroke that most jigsaw blades do.