Unistrut is a recognized name for products that reflect bespoke quality

When looking at channel systems from a wide range of suppliers, you will often see the words “Unistrut compatible” mentioned. This is hardly surprising when Unistrut is the best-known brand and overall market leader in channel support systems. So let’s take a look at Unistrut and find out why the name carries such significance in the field.

A brief history of Unistrut

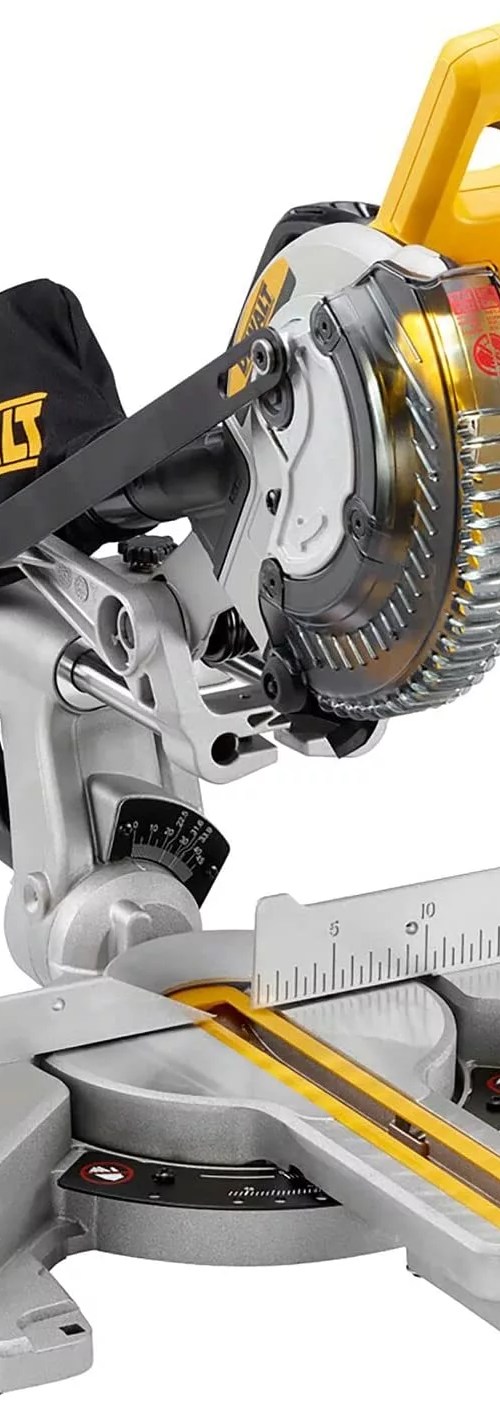

The story of Unistrut goes back to 1924 when its creator Charles Attwood founded the company Deceleco Inc. Attwood developed a system of metal struts combined with brackets and nuts which allowed for systems to be built in a range of configurations without welding. This made installation simple and safer, as well as making the components reusable. The standard 2 x 4 stud, in use at the time, led Attwood to adopt a one-and-five-eighths of an inch profile for his metal channels, which gives rise to the standard 41mm x 41mm profile still in use today. This product was versatile and revolutionary offering an almost unlimited range of potential applications. This utility, combined with in-house production that ensured quality led Attwood’s Unistrut system to become a worldwide success and, despite many imitators, is still the market leader.

Many Applications

The beauty of Unistrut is the wide range of applications on which it can be used. The most common application is for providing support for M&E and HVAC systems, but any situation where a strong light and easily assembled framework is required could be dealt with using strutwork. Cable management is another major area for Unistrut channel support systems. Crucial to this flexibility is the ability to attach further accessories to the channel.

Trusted Worldwide Known Brand

Having been established for nearly a century and being the worldwide market leader, Unistrut has earned a reputation for quality that is unrivalled.

Many other Unistrut compatible brands on the market

Having begun with that standard 41mm x 41mm profile all those years ago and using the specially adapted nuts with their grooves that fit snugly into the channel edges, has meant that any other product entering the same market needs to conform to the Unistrut profile. Any builder seeking to switch supplier for whatever reason will still need to be sure their new strut will work with existing kit. Consequently, most other manufacturers make sure their channel and nuts conform to Unistrut’s main profile specifications.

Unistrut products often specified for projects

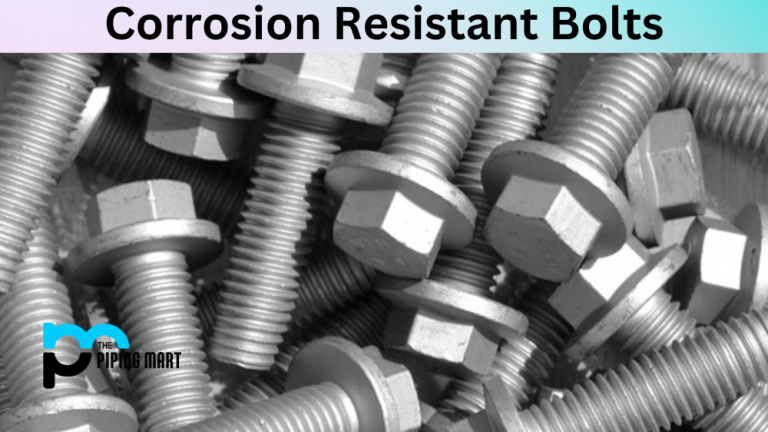

Because Unistrut offers arguably the widest range and best quality specs for channel support systems, they are often the default specification for major construction projects. In particular, London Underground specifies Unistrut for their projects. One major reason for this is that Unistrut provides full anti-corrosion specifications and, for applications such as cable management through tunnels, this is a high priority. Knowing exactly how long struts can be left before being replaced allows London Underground to schedule routine maintenance with confidence.

Unistrut has also been specified for projects including Heathrow Terminal 5 and the Holmesdale Tunnel on the M25; and it’s not just in the UK either. Unistrut are supplying cable ladder and cable trays to the Kashagan oil field in Kazakhstan, for example.

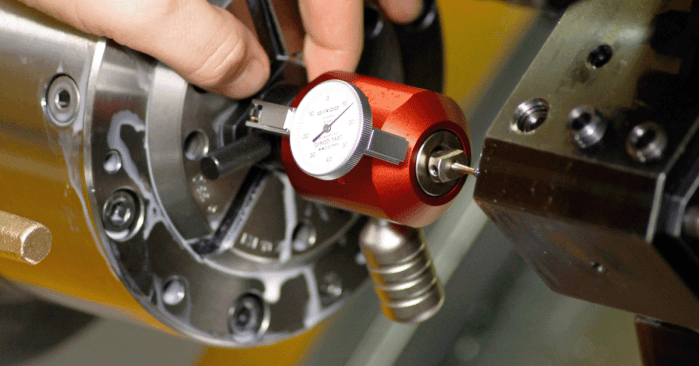

Continued Research and Development

Unistrut was bought in 1995 by Tyco, and in 2010 it became part of Atkore International, but the key to Unistrut’s continued success is ongoing development and consistent quality. By constantly refining and upgrading their product range and specifications they stay one step ahead of the competition.

Additional resources

Making use of support solutions design software for planning a new project, for example, means that you can quickly calculate the components needed and be sure of keeping costs to a minimum while still meeting desired specifications.

Bespoke components

Unistrut offers an unrivalled range of components to suit almost every conceivable situation. Even so, there may be specialised parts which you can envisage but which are not available as standard. Unistrut can provide bespoke components for their systems as indeed they have done for London Underground, with a range of curved sections designed to fit the tight spaces between tunnel walls and trains. So just because a part is not part of the range, does not mean I cannot be made.

Technical Advice and readily available product performance data

Being able to get full specifications and technical advice from the manufacturers can make a huge difference to a project. When installing channel support systems in hostile environments such as maritime or desert, or in installations which will be exposed to extremes of heat or cold, you will want the right level of anti-corrosion treatment and to know the predicted lifetime of a particular product to make it easier to plan routine maintenance.

Product Range

Support Systems

-

Channel (types and finishes)

As well as the standard 41mm x 41mm, channel is available is deep, 62mm, and shallow, 21mm, versions, as well as back-to-back versions of these, both slotted and plain. Most components are available in a range of materials and finishes including pre-galvanised and hot dip galvanised, the latter being superior as the item is galvanised after finishing. There are also stainless-steel channels and other options like aluminium, fibre-glass, and plain steel. Each is suitable for different applications.

Unistrut also has different form factors than the standard 41mm FF and can supply other options beyond back-to-back, e.g. side-to-side, and side-to-back. And don’t forget, if you can envisage it, Unistrut can probably supply it as a bespoke item.

-

Brackets

As with channel, there is a wide range of flat and angled brackets in a range of materials and finishes for different purposes. The variety of bracketry allows for almost any configuration of channel that you can imagine being constructed.

-

Fixings

Channel nuts are available with or without springs, as well as some specialised nuts and pre-studded nuts which come preassembled and are designed for extreme ease and speed of installation. Threads range from M6 to M16 with M8 and M10 being the most common in use.

Cable Containment

-

Cable Tray

Unistrut cable trays are supplied in light, medium, and heavy-duty versions, as well as all the covers, brackets and connectors , needed to make a neat and efficient installation. Full specifications are available as with all Unistrut products.

-

Cable Ladder

For large runs of cable, Unistrut cable ladder provides a quick prefabricated solution. In three main depths 100mm, 125mm, and 150mm. These are supplied in straight lengths, flat curves, T and X junctions, and curved inside and outside risers along with the couplers and accessories to connect everything up. As with all Unistrut products, there are different finishes for different applications and full specifications are available to make sure you are using the right products for your job.