What is the Difference Between Hydraulic Jacks and Screw Jacks?

What is the Difference Between Hydraulic Jacks and Screw Jacks?

Hydraulic jacks and screw jacks are common lifting tools in life. Both types of jacks are used to lift heavy objects.

What are their specific differences?

Now TorcStark will go into detail.

Principle

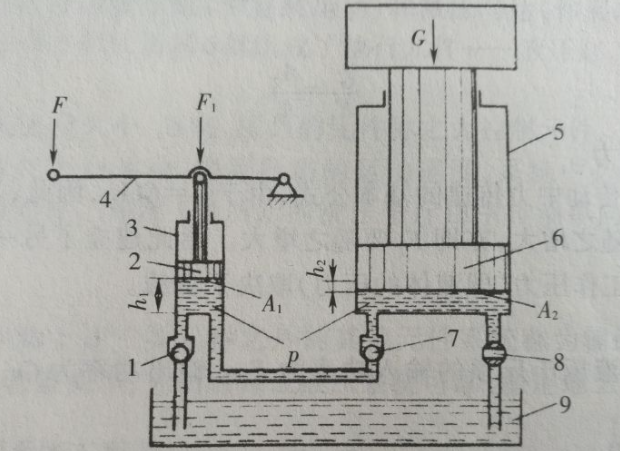

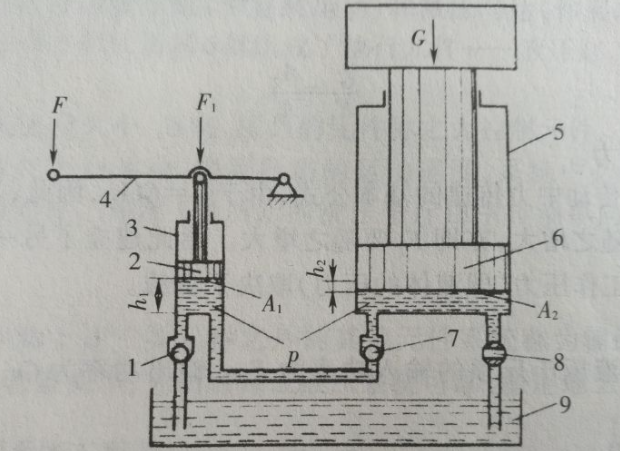

Hydraulic jacks use Pascal’s principle, that is, in a closed container, the pressure on the same level is the same. Its calculation formula is P=F/A, so sometimes a person can still press a car in a closed container. In a balanced system, less pressure is exerted on the smaller piston and more pressure is exerted on the larger piston, which keeps the liquid at rest. Therefore, through the transmission of the liquid, different pressures on different ends can be obtained, so that a transformation purpose can be achieved.

Screw jacks use the relative motion of the screw and the nut to lift or lower heavy objects. It consists of main frame, base, screw rod, lifting sleeve, ratchet group and other main components. When working, it is only necessary to repeatedly turn the handle with the ratchet wrench, and the small bevel gear will drive the large bevel gear to rotate, causing the screw to rotate, so that the lifting sleeve can rise or fall. At present, this kind of jack has a lifting height of 130mm-400mm.

Application

Hydraulic jacks are mainly used in industrial fields, such as bridge jacking, building translation and other large-scale structures.

Screw jacks are commonly used in life, such as vehicle maintenance, mine weight reduction project support and general heavy lifting and lowering.

The two types of jacks overlap in use and can be substituted for each other, but in general, hydraulic jacks are more inclined to the industrial field, and screw jacks are the life field. For example, the hydraulic cylinders produced by TorcStark focus on the jacking, rotation and translation of large structures. With the PLC synchronous jacking system, more complex engineering projects can be completed.

Weightlifting process

Screw jacks lift or lower heavy objects through the relative motion of the screw and nut. When working, it is only necessary to repeatedly turn the handle with the ratchet wrench, and the small bevel gear will drive the large bevel gear to rotate, causing the screw to rotate. The screw jack is purely mechanical operation. When one side gear is manually rotated, it can drive the three ring gears to run at the same time, so as to realize the lifting movement of the threaded spindle.

The lifting and lowering of the hydraulic jack is divided into 3 steps

1. The oil suction process of the pump

When lever handle 1 is lifted by hand, the small piston is driven upward, and the sealing working volume in pump body 2 increases. At this time, since the oil discharge check valve 3 and the oil discharge valve 8 respectively close the oil paths where they are located, the working volume in the pump body 2 increases to form a partial vacuum. Under the action of atmospheric pressure, the oil in the oil tank opens the oil suction check valve 4 through the oil pipe and flows into pump body 2 to complete an oil suction action.

2. The process of pumping oil and lifting heavy objects

When the lever handle 1 is pressed down, the small piston is driven down, the working volume of the small oil cavity in the pump body 2 is reduced, the oil in it is squeezed out, and the oil discharge check valve 3 is pushed open (at this time, the oil suction one-way Valve 4 automatically closes the oil path to the oil tank), and the oil enters the hydraulic cylinder (oil chamber) 11 through the oil pipe. Since the hydraulic cylinder (oil chamber) 11 is also a sealed working volume, the force generated by the incoming oil due to being squeezed will push the large piston up and lift the heavy object to do work. Repeatedly lifting and pressing the lever handle can make the heavy object rise continuously and achieve the purpose of lifting.

3. The process of falling heavy objects

When the large piston needs to return downward, open the oil drain valve 8 (rotate 90°), then under the weight of the heavy object, the oil in the hydraulic cylinder (oil chamber) 11 flows back to the oil tank 5, and the large piston descends to its original position.

Therefore, the hydraulic jack uses the oil as the working medium, transmits the movement through the change of the sealing volume, and transmits the power through the internal pressure of the oil. Hydraulic transmission is essentially an energy conversion device.

Summarize

Hydraulic jacks and screw jacks are one of the tools commonly used in life. If you work in an industrial field, a hydraulic jack will be one of the most familiar tools. If you have any questions about jacks, please contact TorcStark, we will give you the best solution.