What are pliers?

Pliers are versatile tools that are essential for any

toolbox.

You can use them for gripping, bending, cutting, crimping, and more.

In this post, we’re going in deep to understand what pliers

are, their important features and characteristics, and how to use them.

What are pliers and how do they work?

Pliers

are hand tools designed to grip and manipulate objects or cut through tough

materials. They consist of two metal jaws attached to handles and joined

together by a pivot point.

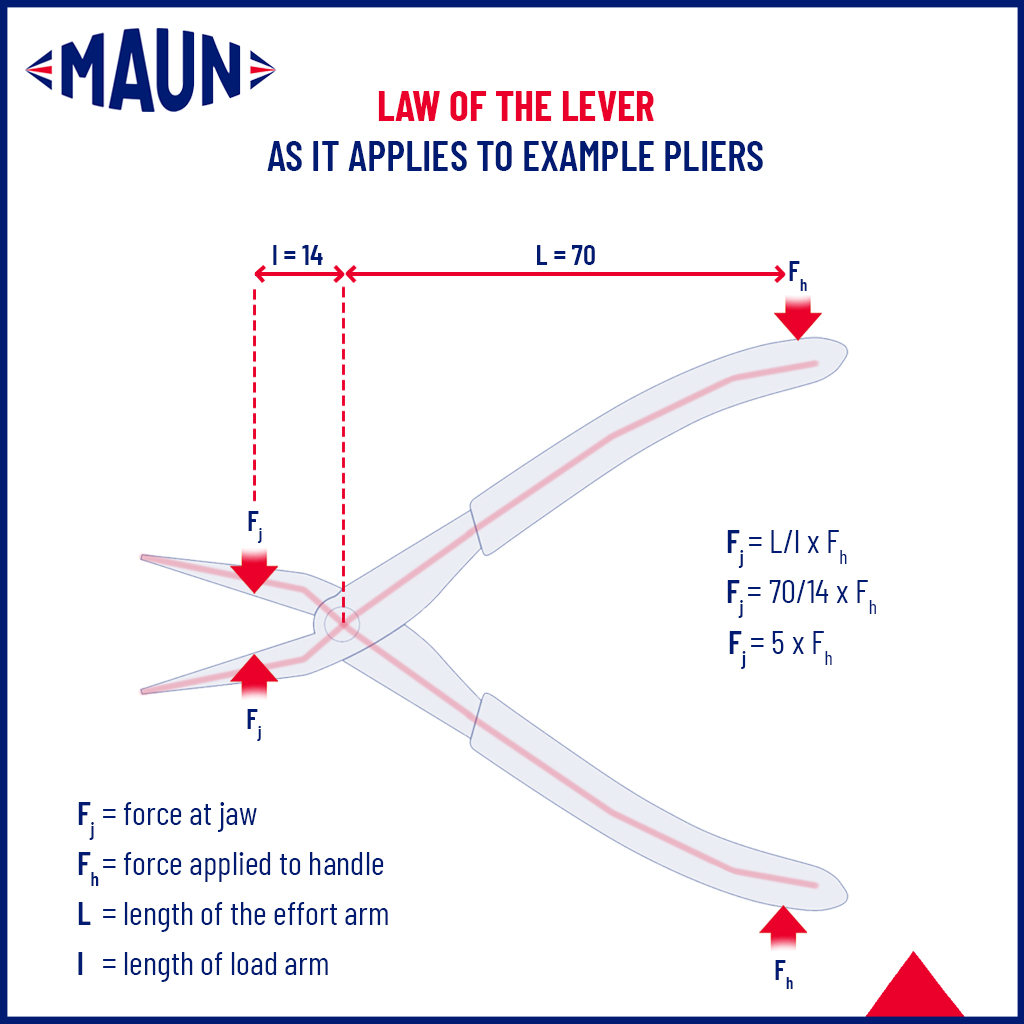

Pliers are so useful because of the “law of the lever”, whereby the

greater distance you have between a lever (the handles) and the pivot point,

the greater force is applied to the other fixed side of the pivot (the

gripping/cutting jaws).

This takes the force applied at the handle end, and greatly

multiplies it into the force applied at the jaw end, allowing a human hand to

grip very tightly, or cut through very hard objects without much effort.

The image above shows how the law of the lever applies to a standard pair of pliers. In the example shown, the force in the middle of the jaws is equal to 5 times the force applied to the handle.

What are pliers used for?

Broadly, pliers are used for gripping, cutting, and bending

objects. There are also pliers designed for specific tasks, such as

tongue-and-groove pliers (for gripping and turning non-uniform nuts) and

insulated pliers (to protect from the dangers of live electrical wires).

We have much more specific information on the uses of pliers

in the following sections:

How to choose pliers

Here we go over the common differentiating factors between

different pliers, and why you may choose each type.

Jaw action

This is the way the plier jaws move, and there are two main

types:

Scissor-action

With scissor-action pliers, the jaws open and close around a

single pivoting joint, in the same way as traditional scissors.

This means the closer you move your workpiece towards the pivoting

joint within the jaws, the more pressure is applied.

They tend to be the cheapest option but aren’t good at

gripping smaller or delicate objects. They’re also harder to use, so your hand

will get tired more quickly than when using parallel-action pliers.

Parallel-action

Parallel

pliers

(also called parallel-action pliers) use a box joint system that

lets the jaws close in parallel to each other.

They are more expensive than scissor-action pliers, but they

provide a much better grip because they create a larger contact area with your

workpiece, which increases friction.

This helps to reduce the energy required for gripping,

allowing you to grip for longer periods. It also allows you to be more accurate

with the way you manipulate objects, particularly important during complex

jewellery designs or manipulating wire.

Learn more about

parallel pliers here

.

Jaw Surface

Serrated Jaws

Serrated jaws on pliers provide extra grip on your

workpiece. They do however risk scratching delicate pieces, and so shouldn’t be

used on soft metals that are intended for show.

Smooth Jaws

Smooth

jaw pliers

are used when you want to preserve the surface of the workpiece,

such as in jewellery or model making, and craft work. These jaws prevent any

indentations or scratches.

V-slot

This isn’t a common feature, but it’s useful when you’re

gripping metal wire. The jaws have a groove that’s designed to hold the wire

all the way around, increasing the surface area and therefore the grip.

Open-throat

Another rare feature is open-throated pliers, can have wire

threaded down the entire length of the tool, which allows you to grip/bend at

any point of a long wire piece. This opens up a range of possibilities that

traditional pliers don’t allow you to do.

*Side note, both the V-slot and open-throat are

features of

Maun

Side Cutter Parallel Pliers

.

Nose Shape

The shape of the plier jaws is referred to as the “nose”.

Here are the common types and their uses:

Flat nose

Flat

nose pliers

are the standard type, with two thick, flat-shaped jaws, ideal

when you need a good grip on easy-to-access objects.

Snipe nose

Snipe

nose

or chain-nose pliers have tapered, pointed jaws that help you be more

precise with your gripping. They’re commonly used in jewellery making,

modelling, or fine electrical work. They allow you to reach into smaller spaces

than traditional pliers too.

Round nose

Round

nose pliers

have at least one jaw that’s rounded, used for creating bends

in wire and metal. This is useful for jewellery making, more specifically for

making rings.

Bent nose

Bent nose pliers have angled jaws that help them to grip at

awkward angles, that straight jaw pliers wouldn’t be able to access. This can

be useful for reaching obstacles in the middle of an existing workpiece.

Needle nose/Long nose

Needle nose and long nose pliers have long, pointed jaws,

ideal for gripping in very hard-to-reach areas.

Cutting Edge

Hardness

The hardness of the pliers’ cutting edge will determine how

long it takes for it to go blunt from use. This is measured using the Rockwell

hardness scale (HRC) that records the depth of penetration of an indenter into

the surface of a material.

Maun recommends you use induction-hardened jaws for cutting

pliers with a HRC value of 57-64.

Cutting edge thickness

The thickness of the cutting edge determines what it’s

useful for. A thicker blade should be used for cutting heavy-duty wire, as this

provides more leverage against a single piece of wire. Whereas cutting through

multiple thinner strands of wire is better with a narrow cutting edge.

Blade angle

The angle of the cutting edge should differ depending on the

material you’re cutting and what you want the final cut to look like.

- Diagonal cutters have a blade at a 45-degree

angle to the handles and are ideal for cutting metal wire or electrical

cables.

- Pliers with straight blades are used to cut through

thinner and softer wire, as well as plastic cable ties.

- End-cutting pliers have flat blades at the end,

designed to trim objects close to a surface.

- Shearing-action pliers act like scissors and

are designed to cut through sheet metal, leather, and rubber.

Blade material

The majority of plier cutting edges will be made from steel.

Maun recommends choosing pliers made from medium- or high-carbon steel, as this

improves durability and helps maintain a sharp cutting edge.

Pliers Size

The larger the pliers you choose, the more leverage they

will have, and so the greater gripping or cutting force you will achieve with

them.

However, if you want to be more precise, then a smaller tool

will give you more control.

So, you need to choose the right size of pliers for the job

you wish to do with them.

For example, 125

mm Snipe Nose Pliers

are great for gripping smaller objects in a tight

space, whereas for cutting and gripping tough hard wire, you’ll want a set of

200

mm Side Cutter Parallel Pliers

.

Pliers for specific tasks

Diagonal cutting pliers

Diagonal cutting

pliers

(also known as “side cutters” or “snips”) are used for cutting

through wire and other materials. They have angled jaws that create a flush

cut, doing so by first indenting the object and then wedging it apart.

Learn more about them here: What

are diagonal cutting pliers?

End cutters

End cutters

(or “end cutting pliers”) are used for cutting wire or nails very close to flat

objects. This is possible because the jaws are perpendicular to the handles,

and they’re very flat.

Learn more about them here: What

are end-cutting pliers?

Plastic jaw pliers

Plastic

jaw pliers

are designed to be non-marking, so you can grip delicate or

fragile materials without damaging them. They are very commonly used in fine

jewellery making.

Crimping pliers

Crimpling pliers are used to install an electrical crimp,

which is a solderless electrical connection, often for terminating stranded

wires or installing them into an electrical terminal.

Learn more about them here: What

is a crimping tool?

Jewellery pliers

Jewellery

pliers

are an overarching category that contains many specific types of

pliers used for jewellery making. This includes forming wire shapes, making

loops, cutting wire, crimping beads, creating jump rings, and gripping smaller

items.

Learn more about them here: What

are jewellery pliers?

| Best

jewellery pliers

Fencing pliers

Fencing

pliers

are a type of pliers designed to install and maintain agricultural

fencing. They’re particularly useful for high-tensile electrical fence wire and will be able to both grip and cut through hard wire.

Learn more about them here: What

are fencing pliers?

| Best

fencing pliers

Combination pliers

Combination pliers usually refer to a set of pliers that

can both grip and cut objects. They do this by having two types of jaws that can

be operated using the same handles, allowing you to quickly switch between

tasks.

Locking pliers

Locking

pliers

are traditional gripping pliers that can be locked in place,

allowing you to let go of the pliers without them becoming loose. This can be

useful when working with multiple objects at once, such as working on an

intricate model.

Tongue-and-groove pliers

Tongue-and-groove pliers (also known as “slip-joint pliers”

or “water pump pliers”) have an adjustable pivot point that lets them be

adjusted to fit multiple sizes of nuts. Usually used by plumbers for adjusting

pipework.

Circlip pliers

Circlip pliers (also known as “retaining ring pliers”) are

designed for installing and removing circlips, which are a type of fastener

that works like a retaining ring (a fastener holding components onto a shaft or

in a bore).

Insulated pliers

Insulated pliers are usually side cutters that have

insulated handles, to stop electrical current conducting through them and

harming a person. They are very commonly used by electricians.

You can learn more about types

of pliers here

.

| Type of Pliers | Primary Use | Advantages | Disadvantages |

|---|---|---|---|

| Parallel Pliers | Provide a firmer grip on surfaces; used on square or hexagonal fastenings and wire. | Spreads pressure over a larger surface area. | May not be suitable for very fine or detailed work. |

| Cutting Pliers | Cut through a wide range of materials. | Minimal hand effort required. | Not designed for gripping or bending tasks. |

| Combination Pliers | Fulfil multiple functions; e.g., gripping, bending, and cutting wire. | Speeds up workflow; reduces need to swap tools. |

The smaller cutting jaws aren’t suitable for very wide materials. |

| End Cutting Pliers | Cut off loose ends of wire; remove nails or old bolts. | Precise flush cutting; can also be used for removal tasks (like old nails). | Limited to end cutting; not as useful for general cutting tasks. |

| Round Nose Pliers | Bend wire; primarily used in jewelry making. | Can form even loops of multiple sizes. | Not suitable for tasks requiring flat grip. |

| Needle Nose Pliers | Grip and bend light materials in confined spaces. | Long jaws for precision work. | Not ideal for heavy-duty tasks due to slender design. |

| Clamping Parallel Pliers | Locking mechanism to hold items without manual grip. | Allows multitasking; firm grip. |

Locking mechanism may get in the way if used in tight spaces. |

| Crimping Pliers | Install solderless electrical connections. | Creates a secure seal/connection. | Specific to crimping tasks; not versatile. |

| Olive Cutting Pliers | Cut olives from pipework. | Safer and more precise than other methods. | Limited to cutting olives; not for general use. |

| Jewellery Pliers | Designed for intricate tasks in jewelry making. | Specifically tailored for delicate work. | Not suitable for heavy-duty or general tasks. |

Using pliers safely

To use pliers, you hold the tool in one hand, place the

workpiece you want to bend or cut in the jaws, then apply gripping force to the

handles.

There are some simple things you can do to ensure you’re

using your pliers safely:

1. Eye protection – make sure to wear goggles when

cutting materials that could harm you.

2. Gloves – make sure your hands are protected

properly when dealing with sharp materials.

3. Long sleeves – this will ensure your skin is

protected from flying bits of sharp metal.

4. Ensure no live wires – never use pliers on live

wires.

Learn more here: How to use

pliers

Maintaining Pliers

To properly care for your pliers, follow these tips:

1. Clean – clean your pliers after each use with a

clean rag, to remove debris or residue.

2. Oil – apply a light coat of oil to the pliers’

jaws to prevent rust.

3. Sharpening – sharpen your tool with a file or

sharpening stone to remove any nicks or burrs.

4. Proper storage – store them in a cool dry place.

Conclusion

We hope you enjoyed our post on pliers.

Browse our related posts below, or contact us with any

questions:

- Cutting

pliers

- Best plier sets

- Best

combination pliers