Unlocking the Potential of Power Drills: A Comprehensive Overview

In the dynamic world of do-it-yourself endeavors and professional construction, the power drill reigns supreme as an indispensable tool, seamlessly blending efficiency with versatility. Whether you’re a seasoned craftsman or a weekend enthusiast, delving into the intricacies of power drills can significantly elevate the outcomes of your projects. This article will delve into the various facets of power drills, and their diverse applications, and shine a spotlight on the significance of “geogrid” in construction ventures.

What are the available types of power drills in the market?

Power drills span a spectrum of types, each meticulously crafted to meet specific requirements. The primary categories include corded and cordless drills. Corded drills excel in continuous use and heavier tasks, while cordless counterparts offer the freedom of movement and convenience for smaller-scale projects. Additionally, specialized drills such as impact drills and hammer drills cater to distinct purposes.

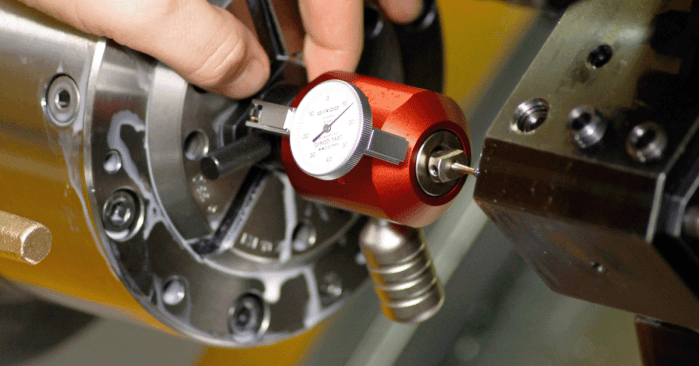

What key features should you consider when acquiring a power drill?

When in the market for a power drill, factor in considerations like power (measured in volts), speed (measured in revolutions per minute or RPM), chuck size, and ergonomic design. Higher voltage and RPM prove beneficial for weightier tasks, and a variable speed setting adds versatility. The chuck size determines the maximum drill bit diameter, while the ergonomic design ensures comfort and efficiency during prolonged use.

What are the prevalent applications of power drills?

Power drills find utility across a broad spectrum of projects, including woodworking, metalworking, masonry, and general repairs. They are indispensable for activities such as drilling holes, driving screws, and even mixing paint or cement. In woodworking, power drills are vital for tasks like affixing hinges and assembling furniture. In construction, their role is pivotal in fastening components securely and drilling into various materials.

How does “geogrid” fit into construction projects involving power drills?

Geogrid, a synthetic material prevalent in civil engineering and construction, enhances soil stability and prevents erosion, providing structural reinforcement to roads, retaining walls, and embankments. Power drills, armed with masonry bits, often come into play to secure geogrids in position, ensuring a dependable and enduring foundation. This application underscores the synergy between power drills and geogrids in crafting resilient and steadfast structures.

In conclusion, gaining insight into the diverse types, features, and applications of power drills is imperative for anyone venturing into a construction or DIY project. The incorporation of “geogrid” in construction projects underscores the manifold uses of power drills, highlighting their crucial role in building resilient and steadfast structures. As technology progresses, power drills continue to evolve, furnishing users with increasingly efficient and versatile tools for their projects.