Angle Grinder Buying Guide for Beginners UK 2023

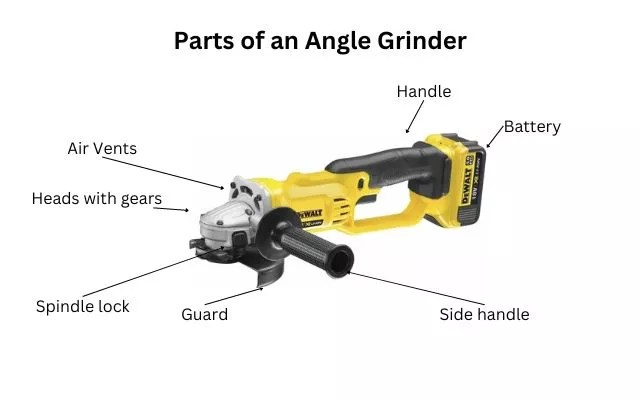

An angle grinder can be a very useful power tool, used mainly for a number of metalworking or woodworking projects The type of projects can range quite a bit, from cutting metal, grinding concrete, cutting tiles, cutting paving stones, sharpening tools, sanding rough surfaces and even polishing certain materials.

The humble angle grinder is a real workhorse, capable of tackling a wide range of tasks with precision and efficiency. Once you get to understand the intricacies of this powerful tool you really can start to use it to its full potential.

Our guide will take you through the key factors that you need to consider when choosing an angle grinder and how to use it safely and effectively. Here at UK Tool Guide, we like to keep our guides informative, helpful and easy to understand.

Types of Angle Grinders

There are three main types of angle grinders:

- Corded angle grinders: Corded angle grinders offer the most power and are typically less expensive than cordless angle grinders. However, they are also less portable and require a UK power socket to operate.

- Cordless angle grinders: Cordless angle grinders are more portable and convenient to use than corded angle grinders. However, they are also more expensive and have slightly less power, which diminishes as the battery power drops.

- Compressed air angle grinders: These tend to be used in garages and workshops where they attach to a large air compressor and are powerful. Homeowners are unlikely to need to own one of this type.

- Corded

- Cordless

- Pneumatic

1. Corded Angle Grinders

The corded type plug into an electrical socket and operate off the normal 230/240V main’s electric. The electric lead is usually around 1.5-2 metres in length. Depending on where you are working you may also need an extension lead. The corded angle grinder delivers a consistent and reliable performance, making them best suited for heavy duty tasks like cutting metal and grinding concrete.

Pros:

Cons:

2. Cordless Angle Grinders

Cordless angle grinders, are powered by rechargeable batteries, (Lithium-Ion) and they offer the ultimate in portability and freedom from cords. These versatile tools are particularly well-suited for tasks in areas with limited access to electricity or in situations where trailing cords are a concern. The most popular size of battery is 18V. In addition to this, you will need a charger for the battery.

Pros:

Cons:

In reality, based on our extensive experience, if you decide to go cordless then here is our recommendation. To make the angle grinder effective, you will need two batteries. That means you can use one and have the other one on charge. To do this you will also need a charger. The batteries really need to be 4.o Ah batteries or larger to get any decent running time. That can make the overall purchase much more expensive. The upside is that you can then buy bare tools from the same brand, which will save you money in the longer term.

3.Pneumatic Angle Grinders

Pneumatic angle grinders, powered by compressed air, provide a unique combination of power and precision. These tools are often preferred in industrial settings and for tasks that require high RPMs, such as sanding and polishing. They are also commonly known in the UK as Air Grinders.

Pros:

Cons:

How much do angle grinders cost in the UK?

Angle grinders cost from £25 to £800 in the UK. That is a huge variation in price. I will explain why there is this huge variation in the price range.

- Brand – We found 57 brands who make angle grinders for the UK market, and many of those have different models available. These range from affordable brands such as Black & Decker, Silverline and Katsu, all the way up to high end brands such as DeWalt, Makita and Milwaukee. Prices vary a lot

- Build Quality – The build quality changes the price point a lot. The better angle grinders have all metal moving parts, brushless motors and are simply better made. That means they will last longer, but also impacts a lot on the price point.

- Size – Grinders come in various sizes starting at around 115mm (4″) and going up to 300mm (12″). The larger the grinder, the bigger the motor is required, and just the sheer size impacts the price point.

- Features – Grinders at the lower price points have very basic features. They get more expensive when you start to add features such as variable speed, quick change blades, quick stop, soft start, etc.

- UK Customer Service – The better brands will have a customer service department and a website where you can order accessories and parts if required. They can also answer any questions you may have, and be able to deal with complaints. The really cheap brands will not have that, and many don’t even have a website or any type of contact details.

- Warranties and Guarantees – Like customer service, the better brands will offer good 2-3 year warranties. The cheaper brands just don’t do that.

So, as you can see, there are several reasons why price points vary so much. As a general rule of thumb you can expect to pay on average:

- Corded – Average UK Price £20-£40 and around £50-£70 for the top brands

- Cordless – Average UK Price £60-£80 and around £100-£150 for the top brands

- Pneumatic – Average UK Price £30-£50 and around £80-£150 for the top brands

Which Brands Sell Angle Grinders in the UK?

During our extensive research we found 57 brands who sell these on the UK market. Some will be familiar names, but there are many who may be new to you. We have listed these below:

- AEG

- Avhrit

- Bosch Home and Garden and Bosch Professional

- Black and Decker

- Blodfune

- Calager

- C P Chantpower

- Craftsman

- Day Plus

- Dewalt

- Dewinner

- Draper

- Duratool

- Ecarke

- Einhell

- Evolution

- Excel

- Eypins

- Fein

- Ferm

- Ferrex

- Festool

- Greenworks

- HiKOKI

- Hilka

- Huhomco

- Hyundai

- Ingco

- Ingersoll Rand

- JCB

- Jectse

- Jusfit

- Katsu

- King Showden

- Kripvery

- Makita

- Metabo

- Milwaukee

- Parkside

- Porter Cable

- Posenpro

- Ryobi

- Silverline

- Skil

- Stanley

- Tilswall

- Topway

- Tough Master

- Trend

- Valuemax

- Vonhaus

- Wesco

- Weytoll

- Workpro

- WORX

- Zerotop

- ZHJAN

Choosing the Right Angle Grinder

If you’re a beginner, I recommend choosing a corded angle grinder with a 115mm or 125mm disc. This type of grinder is Really useful and easy to use, and it’s going to be a good choice for most beginners. If you need a more powerful grinder or a grinder that is more portable, consider a cordless angle grinder.

It is worth remembering that cordless angle grinders are more expensive than corded angle grinders, and they have slightly less power.

When it comes to picking the right type, it depends on several factors, including the type of work you plan to undertake, the power requirements of the tasks, projects, and your budget.

- For heavy-duty tasks that demand consistent power, corded angle grinders are the ideal choice.

- If portability is a priority, cordless angle grinders offer the freedom to work without cord constraints.

- For applications that require high RPMs and precision, pneumatic angle grinders provide a viable solution.

Regardless of your choice, ensure that the angle grinder you select is equipped with appropriate safety features, such as a safety guard, trigger lock, and dust protection. Additionally, invest in the correct safety gear, including safety glasses, gloves, and hearing protection.

With a clear understanding of the different types of angle grinders and their applications, you can confidently select the tool that best suits your needs and empowers you to tackle any project with precision and efficiency.

Power Requirements: Matching the Task to the Tool

The power output of an angle grinder is measured in watts or amps. This is an important factor in determining its suitability for specific tasks. For heavy-duty applications like cutting thick metal or grinding concrete, a powerful angle grinder with a high wattage or amperage is essential to handle the demanding workload.

On the other hand, lighter tasks like sanding or polishing may require a less powerful angle grinder. Opting for a tool with too much power can lead to uncontrollable results and potential safety hazards, while selecting an underpowered grinder can result in frustration and inefficiency.

The actual power rating of the motor of an angle grinder is measured in watts or amps. The higher the power rating, the more powerful the grinder will be. There are a wide range of options from 500-2500 watts.

Wheel Size/Disc Size

The size of the grinding wheel, also known as the disc, plays a significant role in determining the cutting depth and versatility of an angle grinder. Larger wheels, typically 7 inches (180mm) or 9 (230mm) inches in diameter, are ideal for cutting thick materials and deep grooves. They also provide a wider surface area for grinding.

Smaller wheels, typically 4 inches (100mm) or 5 inches (125mm) in diameter, offer greater precision and control for intricate work and tight spaces. They are also lighter and easier to maneuver, making them suitable for prolonged use.

Angle grinders come in a range of disc sizes in the UK. We have listed the most popular sizes below:

- 115mm (4.5″)

- 125mm (5″)

- 150mm (6″)

- 180mm (7″)

- 230mm (9″)

The disc size you choose will depend on the types of projects you plan to use the angle grinder for. If you’re a beginner, it’s a good idea to start with either a 115mm or 125mm disc, as these sizes are the most popular and easy to find accessories for.

Corded vs. Cordless vs. Pneumatic

The power source of an angle grinder significantly impacts its portability, performance, and overall suitability for different applications.

- Corded angle grinders, drawing power directly from an electrical outlet, offer consistent and reliable performance, making them ideal for heavy-duty tasks. However, they are limited by the length of the power cord.

- Cordless angle grinders, powered by rechargeable batteries, provide the ultimate in portability, allowing you to work freely without cord constraints. However, their power output may vary depending on battery level, and they require charging for continuous operation.

- Pneumatic angle grinders, driven by compressed air, offer a unique combination of power and precision. They are often preferred in industrial settings and for tasks that require high RPMs, such as sanding and polishing. However, they require a separate compressed air source and can be noisy in operation.

Safety Features: Protecting Yourself and Your Surroundings

Angle grinders, like any power tool, demand respect and proper safety precautions. When selecting an angle grinder, ensure that it is equipped with essential safety features, such as:

- Safety Guard: A shield that protects the user from chips, debris and sparks.

- Trigger Lock: A mechanism that prevents accidental activation of the tool.

- Dust Protection: A system that minimises dust exposure to the user and the work area.

Budget Considerations: Balancing Cost and Performance

Angle grinders come in a range of prices, reflecting their features, power output, and brand reputation. It is essential to set a realistic budget based on your needs and expectations. For infrequent or DIY projects, a less expensive model may suffice. However, for professional or heavier use, investing in a more durable and powerful angle grinder can provide long-term value.

Matching Your Needs to the Perfect Angle Grinder

Selecting the right angle grinder is a personal decision that really depends on the type of work you plan to undertake, the power requirements of your projects, your budget, and your comfort level with the tool. By carefully considering these factors and prioritising safety, you can confidently choose the angle grinder that perfectly complements your tool kit and allows you to tackle any project with precision and efficiency.

Other Features to Consider

- Spindle Lock

- Electric Brake

- Dust extraction port

- Anti-restart feature

- Speed Control

1. Spindle Lock

A spindle lock makes it easy to change discs. It is a pretty simple mechanism that locks the spindle into place and stops it from rotating. Once that is done, you can easily remove and replace the blade. You normally find it on the top of the grinder and will either be a button or a lever. that will vary depending on the brand and model.

2. Electric Brake

An electric brake stops the disc quicker when you release the trigger. It’s essentially a very good safety factor. When you take your finger off the trigger, the disc will still continue to spin for a few seconds. An angle grinder with an electric brake stops spinning a great deal faster. It can be really useful if you are working in a tight space or if you are making really precise cuts.

3. Dust extraction port

A dust extraction port allows you to attach a vacuum cleaner to the grinder to collect dust and other debris. This is usually called a port and is usually found on the rear of the grinder, though some models use a side port.

4. Anti-restart feature

This feature stops the grinder from restarting if there happens to be some type of power interruption. The grinder won’t start again until you have released the trigger and then pressed it again.

5. Speed Control

Most angle grinders have variable speed control, which allows you to adjust the speed of the disc to match the material you are working with. This is an important feature to consider, especially if you are new to using an angle grinder.

The speeds can range anywhere from 2,000-13,000 revolutions per minute (RPM) It is important to be able to control the speed. Here are a few examples;

- Wood – 2,850-4800 RPM

- Metal – 7,000-8,000 RPM

- Plastic – 1,900-3,500 RPM

- Tiles – 4,000-6,000 RPM

- Concrete & Brick 4,000-6000

The important takeaway is that having variable speed on your angle grinder is really important.

Using an Angle Grinder Safely

When using an angle grinder, it’s important to follow certain safety precautions to avoid injury. I would highly recommend that before picking up an angle grinder, make sure that you are equipped with the appropriate personal protective equipment (PPE) to safeguard yourself from potential hazards:

Here are a few tips:

- Always wear safety glasses, ear protection, and gloves. These essential shields protect your eyes from flying debris, sparks, and metal fragments. Choose glasses that fit snugly and provide a wide field of vision.

- Use good quality gloves – Good leather or heavy-duty rubber gloves protect your hands from abrasions, cuts, and burns. Ensure they fit well and provide dexterity for maneuvering the tool.

- Wear ear protection – Earplugs or earmuffs effectively reduce the loud noise generated by angle grinders, preventing hearing damage.

- Respiratory Protection: If working with materials that produce dust or fumes, wear a dust mask or respirator to protect your lungs from harmful particles.

- Make sure the grinder is unplugged or the battery is removed before attempting to change discs.

- Use sharp discs as they make cleaner cuts and greatly reduce the risk of kickback.

- If possible, clamp the workpiece in place before cutting or grinding.

- Hold the grinder firmly with both hands and keep your fingers away from the disc. Avoid one-handed use, which can lead to loss of control and potential injuries.

- Stand with a stable stance, feet shoulder-width apart, to provide balance and prevent accidental tipping.

- Be aware of the grinder’s cord or battery pack and try to make sure it doesn’t get in the way of the disc.

- Make sure the disc is properly aligned before you start cutting or grinding. Maintain a consistent and controlled angle when cutting materials. Avoid sudden changes in direction or excessive force, which can cause kickback or material breakage.

- Grinding Technique: Apply moderate pressure when grinding to avoid overheating the wheel or causing excessive dust generation. Move the grinder steadily across the workpiece in a controlled manner.

- Be careful when cutting or grinding curves or circles.

- Clean the grinder regularly to keep it in good condition.

Angle Grinder Applications

Angle grinders can tackle a diverse range of tasks, from cutting through stubborn metal to polishing delicate surfaces. With the right technique and appropriate accessories, these can be powerful and useful tools for both DIY enthusiasts and professional craftsmen.

- Cutting Metal: Shaping and Forming – They excel at cutting a variety of metals, including steel, aluminum, and copper. With the correct grinding wheel, you can effortlessly cut through metal sheets, pipes, and bars, making them ideal for metalworking projects, construction work, and home repairs.

- Grinding Concrete: Smoothing Rough Surfaces and Leveling Uneven Floors – When equipped with diamond grinding wheels, are the go-to tools for smoothing rough concrete surfaces, removing blemishes, and leveling uneven floors. They are also effective for removing paint, adhesives, and other unwanted coatings from concrete surfaces.

- Polishing Metal: Restoring Shine and Enhancing Appearance – For a gleaming finish on metal surfaces, angle grinders paired with polishing wheels are the perfect solution. They effectively remove scratches, oxidation, and rust, restoring the shine and luster to metal objects, tools, and machinery.

- Sharpening Tools: Restoring the Edge and Enhancing Performance – Angle grinders, equipped with sharpening wheels, can effectively sharpen a variety of tools, including lawn mower blades, axes, chisels, and drill bits. They provide precise control and the ability to restore a sharp edge, enhancing the performance and safety of your tools.

- Grooving and Routing: Creating Precise Channels and Inlays – Angle grinders, with the appropriate cutting wheels, can create precise grooves and channels in various materials, including wood, plastic, and stone. This capability makes them valuable for inlay work, electrical wiring channels, and decorative designs.

- Removing Rust and Corrosion: Combating Decay and Restoring Integrity – Angle grinders, equipped with wire brushes, effectively remove rust, corrosion, and loose paint from metal surfaces. This process not only restores the appearance of metal objects but also protects them from further deterioration.

Angle grinders, with their versatility and adaptability, can be a great tool in the hands of DIY enthusiasts, professionals, and craftsmen alike. Their ability to tackle a wide range of tasks, from cutting and grinding to polishing and sharpening, makes them a true asset in any workshop or toolbox. Whether you’re shaping metal, smoothing concrete, or restoring a tool’s edge, angle grinders are ready to unleash their power and transform your projects into successes.

What accessories can you buy for an angle grinder?

There are quite a few accessories and we have listed those below:

- Cutting discs: These can be used for cutting through metal, concrete, and other materials. They come in a variety of sizes and materials, including diamond, ceramic, and aluminum oxide. Usually sold in packs of 6 or 12 and cost around £1 per disc

- Grinding discs: These can used for grinding down metal, concrete, and other materials. They come in a variety of sizes and materials, including diamond, ceramic, and aluminum oxide. Usually sold as separate items and vary in price quite a lot.

- Sanding discs: Sanding discs are used for sanding down wood, metal, and other materials. They come in a variety of grits and materials, including aluminum oxide and silicon carbide. Normally sold in sets of various sizes and again vary in price quite a lot.

- Wire brushes: Wire brushes are used for removing rust, paint, and other coatings from metal surfaces. They come in a variety of sizes and materials, including steel and brass. These come either as wheel brushes or cup brushes and sold in packs usually. A 4 pack costs around £12-£15

- Backing pads: Backing pads are used to hold sanding and polishing discs in place. They come in a variety of sizes and materials, including rubber and foam.

- Cutting guides: Cutting guides are used to help you make precise cuts in metal, concrete, and other materials. Cost between £10-£30 depending on the brand.

Maintenance and Inspection

Try to develop a routine maintenance schedule, so as you can keep your angle grinder in top condition, preventing unexpected breakdowns and ensuring its reliability for years to come.

Cleaning and Lubrication: Keeping the Tool Clean and Smooth Running

After each use, take the time to clean your angle grinder thoroughly. Wipe down the tool to remove dust, debris, and metal filings. Use a dry brush to clean the ventilation ports and other areas prone to dust accumulation. Regularly lubricate moving parts, such as bearings and gears, using a high-quality lubricant recommended for angle grinders.

Wheel Inspection: Ensuring Wheel Integrity and Safety

Inspect the grinding wheel regularly for cracks, chips, or uneven wear. Replace damaged wheels immediately to prevent breakage and potential injury. Choose the appropriate grinding wheel for the task at hand, ensuring compatibility with the material being worked on.

Cord Condition: Maintaining Electrical Safety

For corded angle grinders, inspect the power cord regularly for damage or fraying. Replace damaged cords immediately to prevent electrical hazards. Avoid exposing the power cord to excessive heat, sharp edges, or excessive bending.

Safety Guard Integrity: Protecting Yourself from Hazards

Ensure the safety guard is securely attached and functioning properly. Clean the guard regularly to remove dust and debris, allowing for unobstructed view of the work area. Never operate the angle grinder without the safety guard in place.

Storage: Keeping Your Angle Grinder Safe and Protected

When not in use, store your angle grinder in a clean, dry, and secure location. Avoid storing the tool in humid or damp environments to prevent corrosion. Protect the tool from extreme temperatures and direct sunlight.

When properly maintained, these can give you years of reliable performance and versatility. By setting aside just a little time to regular cleaning, lubrication, and inspection, you can safeguard your angle grinder from premature wear and tear, ensuring its effectiveness for countless projects. Regular maintenance and inspection of your angle grinder are crucial for maintaining the best performance and preventing safety hazards.

Final Buying Tips & Help

- Consider your budget. Angle grinders in the UK can range in price from around £30 to £300. If you’re a beginner, you don’t need to spend a lot of money on a grinder.

- A basic corded angle grinder has a UK average price of around £35. Something like the Black+Decker 710 W Grinder, or the Einhell 115mm Angle Grinder are typical of this range.

- Cordless angle grinders start at around £45 and can get really expensive at around £150. If you then add a couple of batteries and a charger, they can cost anything between £80-£300. Something like the Einhell Power X-Change 115mm is the best value at around £80-£100.

- We would also recommend reading reviews of different angle grinders before you buy one. This will help you to get an idea of the pros and cons of each grinder.

- If possible, try to use the grinder before you buy it. This will give you a chance to see how it feels and handles.

- Be sure to use the right disc for the job. There are different types of discs available, each designed for a specific purpose.

- They come in a variety of prices and features from many different brands such as Makita, DeWalt, Milwaukee, Bosch, Black & Decker, Ryobi, Einhell etc. Choose the right grinder for your needs and budget.

- There are many different types of angle grinder discs available. Choose the right disc for the material you are working with.

An angle grinder can be a useful tool for any beginner. By following the tips in this guide, you can choose the right saw for your needs and use it safely and effectively. They can achieve a wide range of tasks, from cutting and grinding to polishing and sharpening, makes them really useful. By following the guidance in this guide, you can confidently select the right angle grinder for your needs, operate it safely and effectively, and maintain it to ensure years of reliable performance.