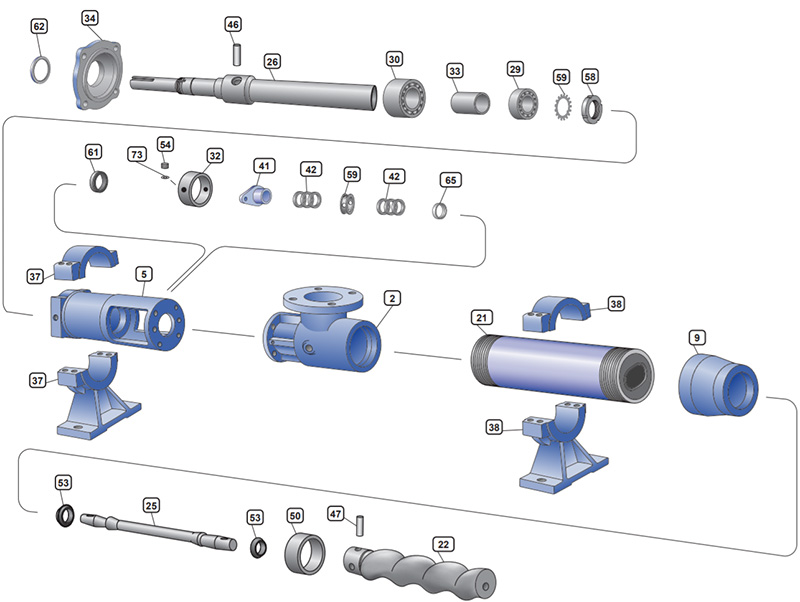

Understanding the Tarby Pump Parts List

When it comes to maintaining and repairing Tarby pumps, having a comprehensive understanding of the parts list is essential. The Tarby pump, known for its reliability and efficiency, consists of various components that work together to ensure optimal performance. This article aims to provide an overview of the key parts found in the Tarby pump and their functions.

Key Components of the Tarby Pump

The Tarby pump is made up of several vital parts, each serving a specific purpose. Familiarity with these components can aid in troubleshooting and maintenance. Below is a list of the primary parts typically found in a Tarby pump:

- Pump Housing

The pump housing encases all internal components, providing structural integrity and protecting them from external elements. It is designed to withstand high pressures and corrosive environments. - Impeller

The impeller is a rotating component that moves fluid through the pump. Its design is crucial for creating the necessary pressure to transport liquids effectively. - Suction Strainer

This component filters out debris and contaminants from the fluid before it enters the pump. A clean suction strainer is vital for preventing damage to internal components. - Mechanical Seal

The mechanical seal prevents fluid leakage from the pump. It is essential for maintaining pressure and ensuring the efficiency of the pump. - Bearing Assembly

Bearings support the rotating parts of the pump, reducing friction and wear. Proper lubrication and maintenance of the bearing assembly are crucial for the pump’s longevity. - Wiring and Electrical Components

The electrical components, including wiring and control systems, ensure that the pump operates efficiently. These parts need regular inspection to prevent electrical failures.

Importance of Each Component

Understanding the function of each component is important for effective maintenance. Here’s a brief overview of why each part matters:

- The pump housing protects the integrity of the pump and houses all internal parts, making it the first line of defense against environmental factors.

- The impeller is integral to the pump’s operation, as its design directly influences the flow rate and efficiency of fluid movement.

- A clean suction strainer is essential for optimal performance, ensuring that contaminants do not compromise the pump’s functionality.

- The mechanical seal plays a crucial role in preventing leaks, which can lead to efficiency losses and potential damage to other components.

- The bearing assembly is vital for smooth operation; any neglect can lead to increased wear and tear, resulting in costly repairs.

- The wiring and electrical components are essential for the pump’s operation. Regular checks can prevent unexpected breakdowns and ensure the system runs smoothly.

Conclusion

Understanding the Tarby pump parts list is crucial for anyone involved in the maintenance or operation of these pumps. Familiarity with each component enables effective troubleshooting and helps prolong the life of the pump. Regular inspections and maintenance of these parts can prevent costly repairs and ensure that the pump operates at its best. By keeping the parts in good condition, users can maximize the efficiency and reliability of their Tarby pumps.