Is the Pump Curve for Progressive Cavity Pump Right for You?

Understanding the pump curve for a progressive cavity pump is crucial for determining its suitability for your specific application. This guide will help you evaluate whether the pump curve aligns with your operational needs.

1. What is a Pump Curve?

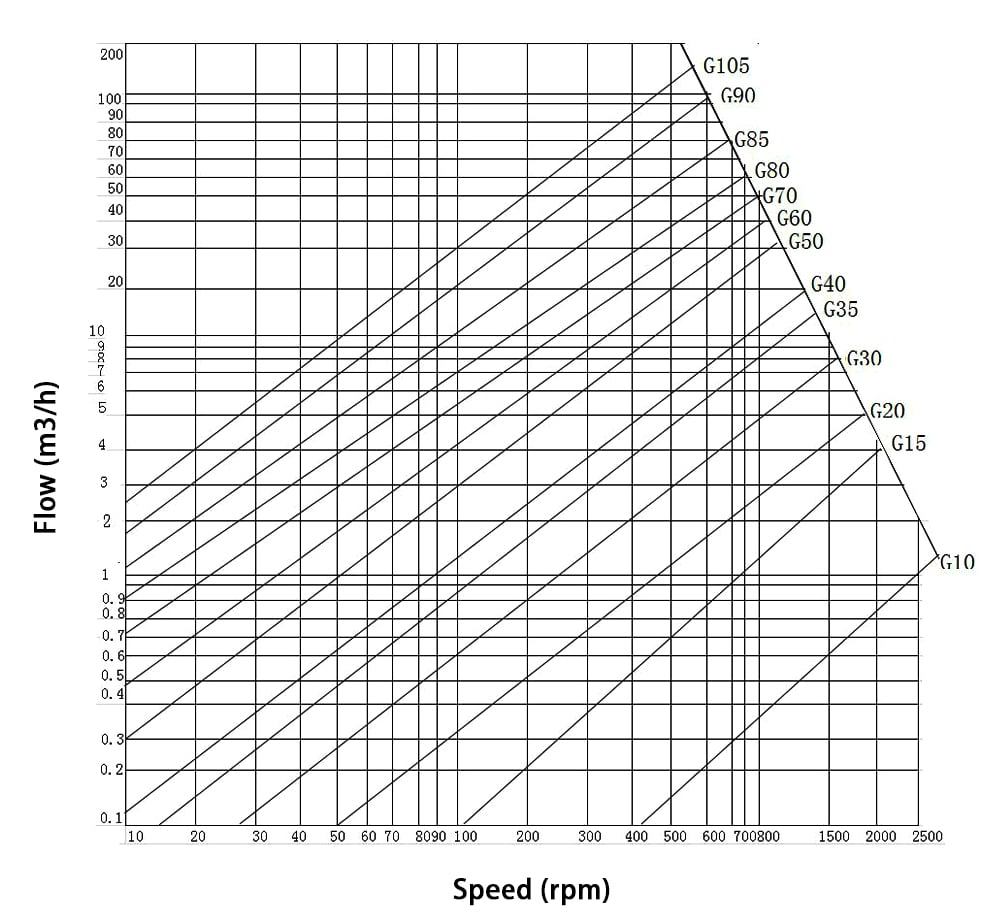

- Definition: A pump curve is a graphical representation that illustrates the relationship between flow rate (GPM or m³/h) and the head (pressure) that a pump can generate.

- Importance: It helps engineers and operators understand how a pump will perform under various operating conditions.

2. Key Elements of a Pump Curve

A. Flow Rate

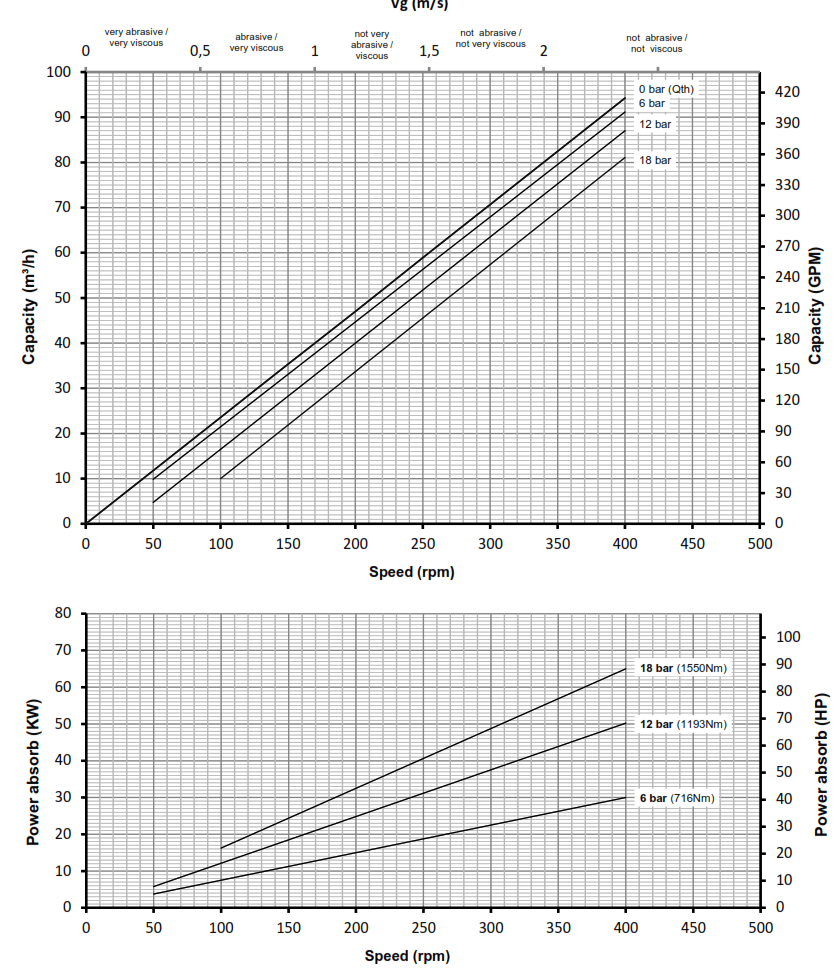

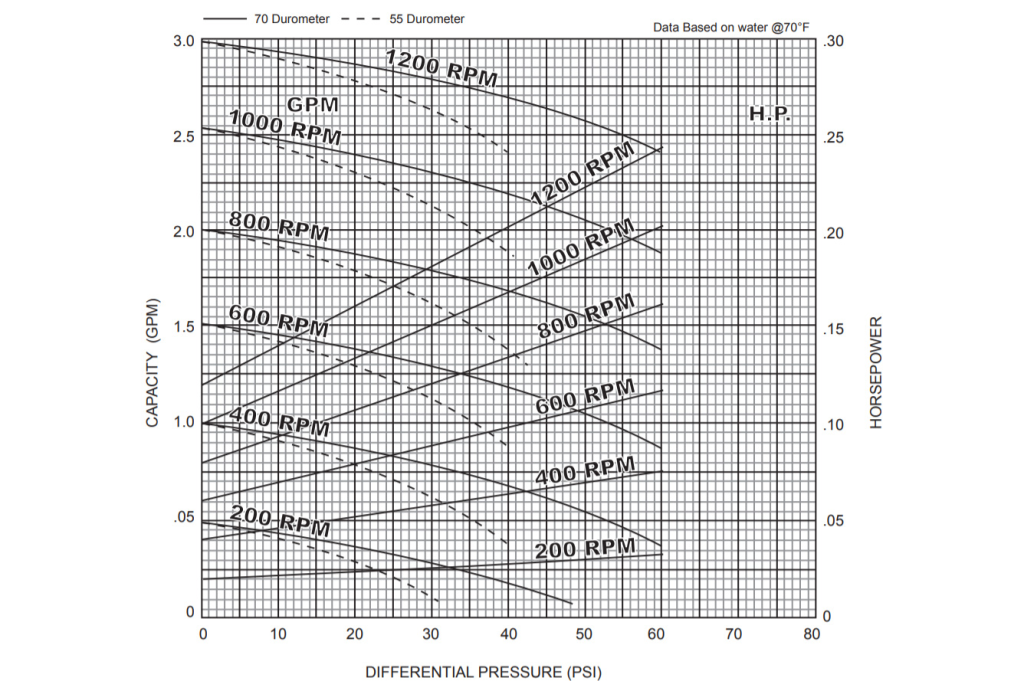

- Definition: The volume of fluid the pump can move, typically measured in gallons per minute (GPM) or cubic meters per hour (m³/h).

- Considerations: Ensure that the pump can handle the required flow rate for your application.

B. Total Dynamic Head (TDH)

- Definition: The total height that the pump can lift the fluid, accounting for both static lift and friction losses in the system.

- Considerations: Confirm that the TDH matches the resistance in your system, including elevation changes and pipe friction.

C. Efficiency Curve

- Definition: Shows the pump’s efficiency at various flow rates, indicating how effectively the pump converts input power to hydraulic power.

- Considerations: Aim to operate within the pump’s best efficiency point (BEP) for optimal performance and minimal energy consumption.

D. Power Requirements

- Definition: The amount of power needed to operate the pump at different flow rates and heads.

- Considerations: Ensure that your power supply can meet the pump’s requirements at the desired operating point.

3. Evaluating the Pump Curve for Your Needs

A. Match Flow Rate and TDH

- Determine Application Requirements:

- Calculate the required flow rate and TDH for your specific application.

- Select a Suitable Pump:

- Choose a progressive cavity pump whose curve intersects your required flow and TDH.

B. Consider Fluid Characteristics

- Viscosity and Density:

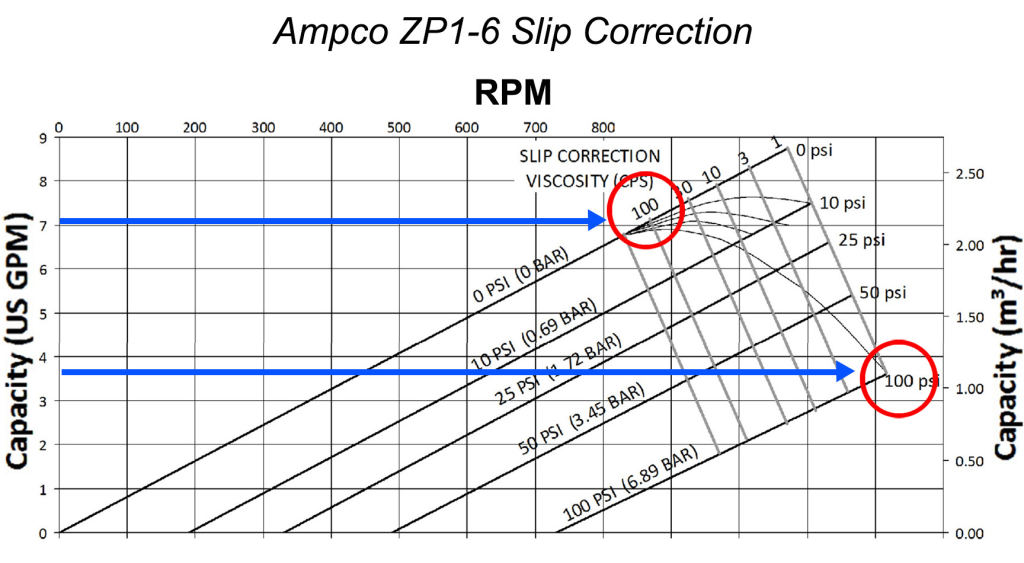

- Assess how the fluid’s properties may affect the pump’s performance and the shape of the pump curve.

- Shear Sensitivity:

- Ensure the pump can handle shear-sensitive fluids without degradation.

C. Analyze Efficiency and Operating Costs

- BEP Focus:

- Select a pump that operates near its BEP to maximize efficiency and minimize energy costs.

- Long-Term Costs:

- Consider both initial purchase price and long-term operating costs based on energy consumption and maintenance.

D. Review System Design

- Piping and Valves:

- Analyze how your piping layout, valves, and fittings may impact the overall system resistance and pump performance.

- Installation Requirements:

- Assess the pump’s installation needs, including space and accessibility for maintenance.