replacement frack pump motor

The Importance of Replacement Frack Pump Motors in Hydraulic Fracturing

Hydraulic fracturing, commonly known as fracking, has revolutionized the energy industry, enabling the extraction of oil and natural gas from previously inaccessible reserves. At the heart of this process is the frack pump, a vital piece of equipment responsible for injecting high-pressure fluid into subterranean rock formations. However, like all machinery, frack pumps can experience wear and tear, making the role of replacement frack pump motors crucial for maintaining operational efficiency and safety.

Understanding Frack Pump Motors

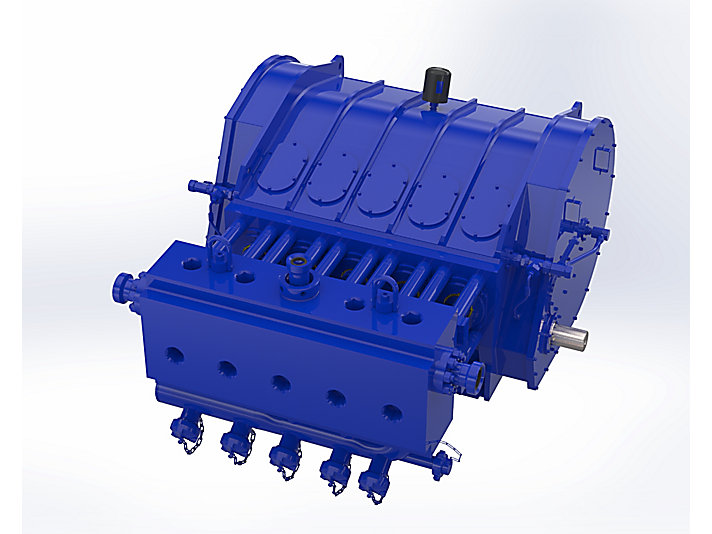

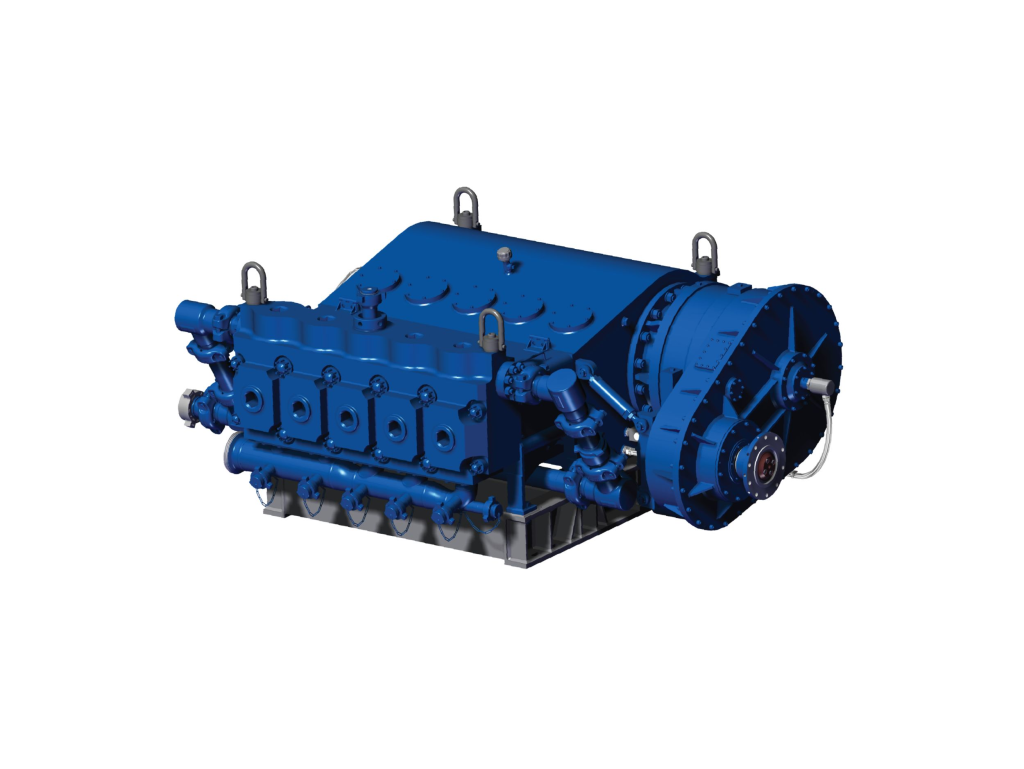

Frack pump motors are designed to provide the necessary power to pump high volumes of fluid at extremely high pressures. These motors are typically large, robust, and built to withstand the harsh conditions often encountered on drilling sites. The demand for reliability and efficiency in fracking operations means that any downtime caused by motor failure can result in significant financial losses.

When a frack pump motor starts to show signs of wear, it can lead to several operational issues, including reduced flow rates, increased energy consumption, and even complete pump failure. Therefore, having a strategy in place for upgrading and replacing these motors is vital for any fracking operation.

The Role of Replacement Frack Pump Motors

Replacement frack pump motors play several important roles in hydraulic fracturing operations:

- Enhanced Efficiency: New motors can significantly improve the performance of fracking equipment. Advanced motor technology often leads to better energy efficiency, which can reduce operational costs in the long run.

- Reliability and Safety: Aging frack pump motors pose a risk not only to production schedules but also to the safety of the entire operation. By regularly replacing these motors, companies can minimize the risk of malfunctions that could lead to dangerous situations.

- Reduced Downtime: The oil and gas industry is under constant pressure to meet production targets. The failure of a single frack pump motor can halt operations for hours or even days. By proactively replacing motors before they fail, companies can maintain continuous operation and ensure project timelines are met.

- Cost-Effectiveness: While the upfront cost of a new motor may seem significant, the long-term savings from improved efficiency and reduced downtime can far outweigh these initial expenses. Companies that invest in replacement frack pump motors often see a significant return on investment through enhanced productivity.

Selecting the Right Replacement Frack Pump Motor

Choosing the appropriate replacement frack pump motor involves several considerations:

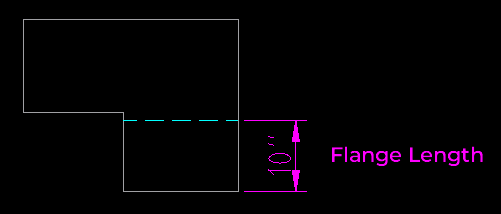

- Power Rating: It’s essential to select a motor that matches the power requirements of your specific frack pump model. Undersized motors can lead to inefficiencies, while oversized motors may increase operational costs unnecessarily.

- Durability: The chosen motor must withstand the extreme conditions typical in fracking operations, including temperature fluctuations, exposure to corrosive chemicals, and heavy vibrations.

- Energy Efficiency: Opting for motors that incorporate the latest energy-efficient technologies can greatly reduce operating costs. This not only benefits the bottom line but also supports efforts to minimize the environmental impact of fracking operations.

The Future of Frack Pump Motors

As technology continues to advance, so too will the design and functionality of replacement frack pump motors. Innovations like variable frequency drives (VFDs) and smart motor controllers will enhance operational flexibility and monitoring capabilities, allowing for real-time adjustments based on site conditions.

Moreover, sustainability is becoming an increasingly important consideration for the energy sector. Future frack pump motors may integrate renewable energy solutions or be designed to align with green technology initiatives, further reducing the environmental footprint of hydraulic fracturing.

Conclusion

In conclusion, the significance of replacement frack pump motors in hydraulic fracturing cannot be overstated. As the industry evolves and faces new challenges, ensuring that fracking operations utilize reliable and efficient motor systems will be critical. By prioritizing the replacement and maintenance of frack pump motors, companies can enhance operational efficiency, reduce risks, and achieve greater safety in one of the most demanding sectors of the energy industry. Investing in quality replacement frack pump motors is not just a financial decision; it is a strategic move toward a sustainable and prosperous future in energy extraction.