Introduction to Pneumatic Torque Wrench

Introduction to Pneumatic Torque Wrench

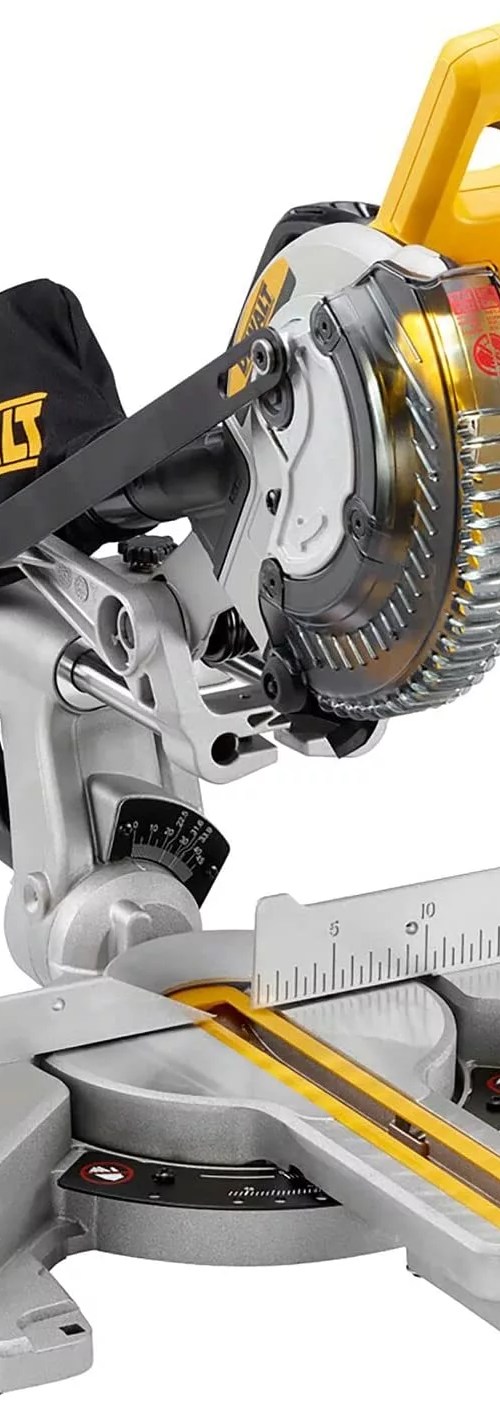

A pneumatic torque wrench is a torque wrench powered by a high-pressure air pump. It is a torque multiplier with three or more layers of epicyclic gears driven by one or two powerful air motors. Its torque is controlled by adjusting gas pressure and is designed to allow for a specific torque demand. Each tool comes with a dedicated air-torque comparison chart and calibration report. For further application, the pneumatic torque wrench can be equipped with a torque sensor at the same time to make the output torque more accurate. The air supply can be switched off manually or automatically using a suitable circuit system after the required torque has been achieved.

Pneumatic wrenches are generally divided into two categories. The first is conventional, which is very common. The difference between the two is that the former cannot set torque, while the latter can. Pneumatic torque wrenches fall into the latter category.

Advantage

In the production line or when a large number of nuts must be locked, choosing the pneumatic torque wrench with a power device can save a lot of work time and manpower, and effectively improve work efficiency.

The operation of the pneumatic torque wrench is quiet – less than 85dB(A), with absolutely no impact, reducing damage to tools, sockets and locked objects. These two factors allow the person using the tool to operate comfortably, reduce fatigue, and improve safety. The maximum torque can reach 300,000N.m.

Pneumatic torque wrenches provide precise torque control – ±5% repeatability. Equipped with sensor + solenoid valve switch, the repeatability can reach ±2%.

The pneumatic torque wrench has the advantages of small size, lightweight and high output power per unit weight, which can achieve large torque output, small reaction force, low environmental pollution and low cost. It is widely used in aerospace, mining, petrochemical, railway, construction, heavy vehicle assembly and maintenance, heavy equipment loading and unloading and many other fields, especially in product production assembly lines, and especially for occasions requiring high torque.

Application

The stable and continuous torque output of the pneumatic torque wrench makes it widely suitable for torque control of various nut and nutless connections.

With nuts:

Pneumatic torque wrenches are suitable for tightening or removing large nuts.

Here are some of its applications:

◆Truck tire bolts, buses and large machinery;

◆Building steel frame structure;

◆High pressure connections, such as pipelines, boiling water pumps and pressure conduits;

◆The nut of the engine head;

◆Injection head on plastic injection molding machine;

◆ heat exchanger;

◆Heavy vehicle products, such as: nuts for car chassis and suspension devices.

Without nut:

When continuous high torque is required, pneumatic torque wrenches can be used if a source of energy is available.

Typical occasions include:

◆Operation of ball valve;

◆Large trucks and overhead mobile cranes;

◆In construction, pneumatic torque wrenches are used in heavy equipment assembly

◆Reel adjustment of steel mills and paper mills;

◆Pneumatic valve.

TorcStark Latest Product —-Pneumatic Torque Wrench

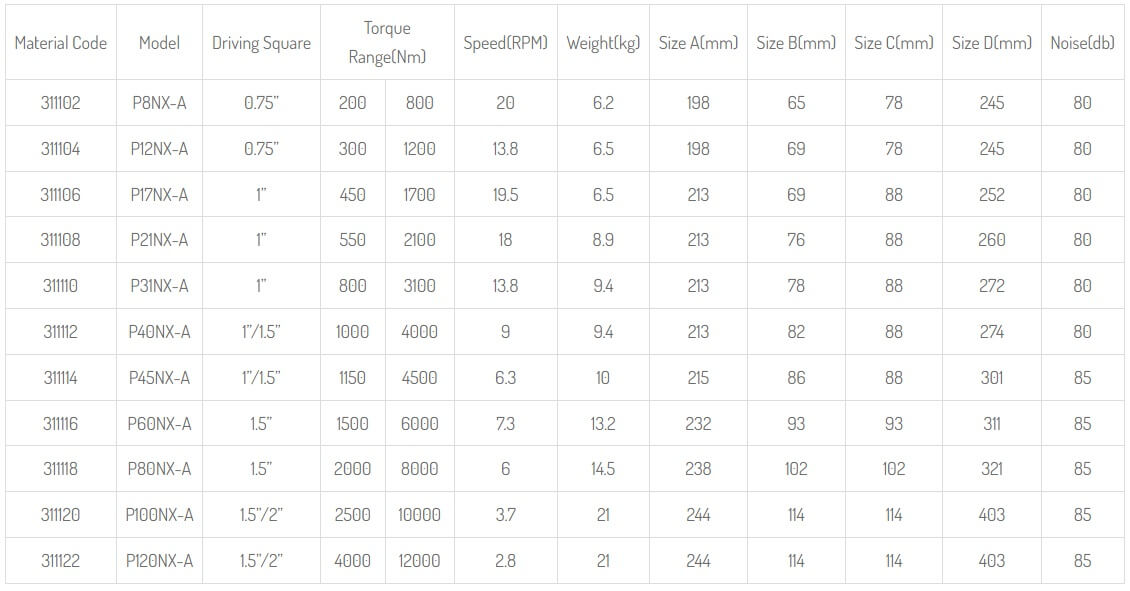

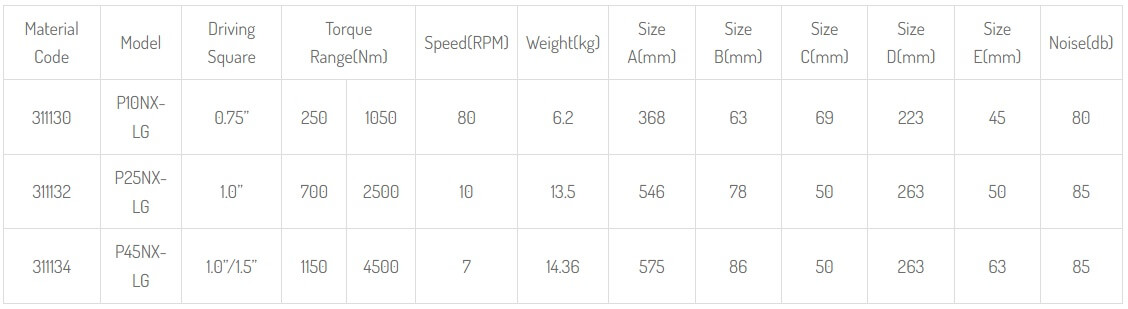

TorcStark’s latest PNX series of pneumatic torque wrenches have a wider torque range and use a multi-stage gearbox for unmatched reliability and stability. Under the correct air supply pressure and air volume, it can achieve an accuracy of ±5% and a repeatability of ±2%.

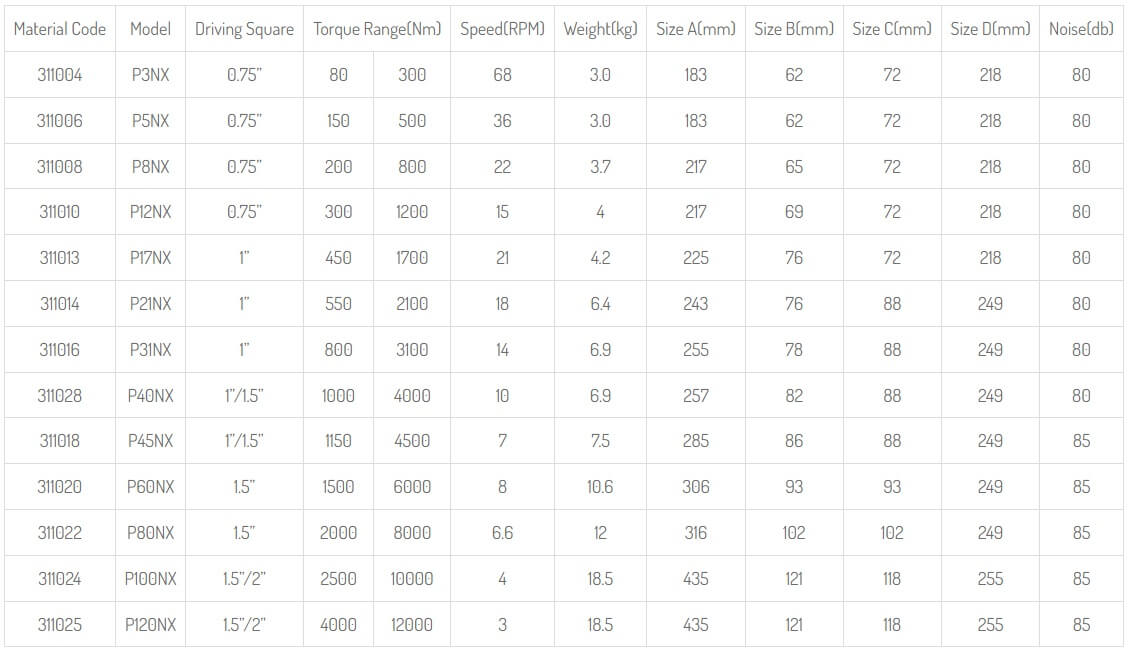

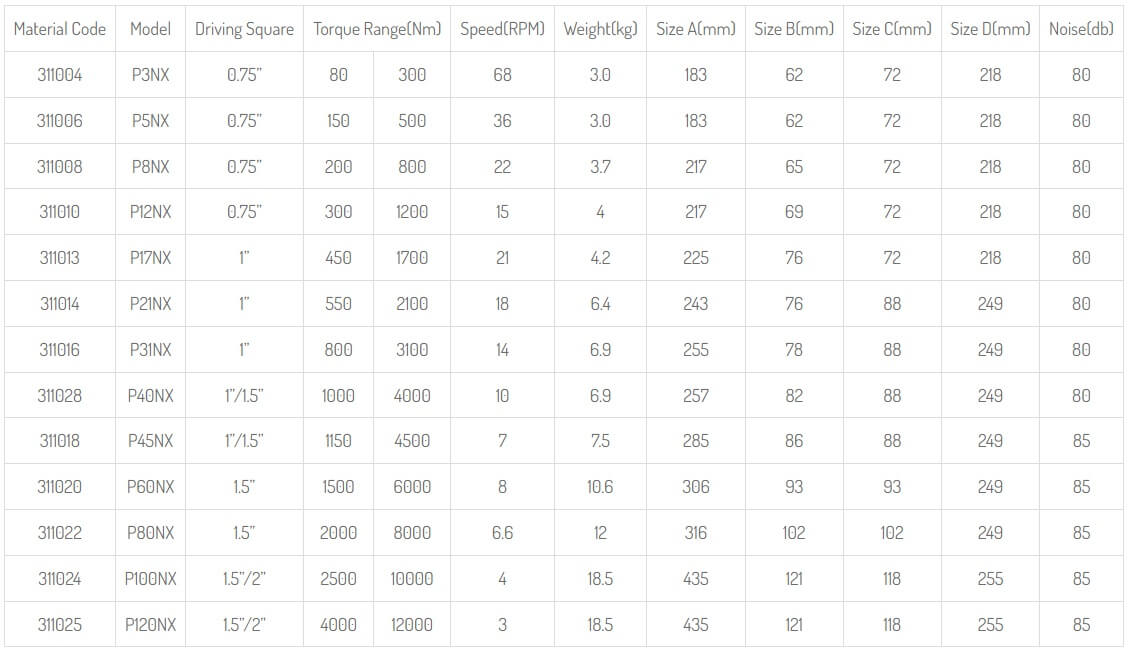

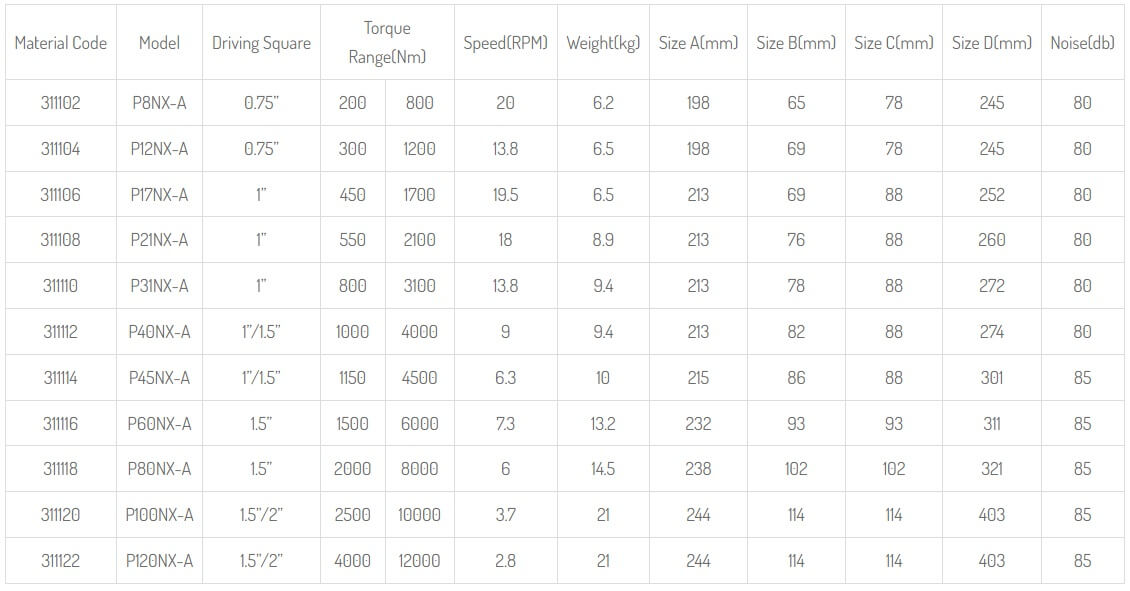

The following are the parameters of the TorcStark pneumatic torque wrench

Pneumatic torque wrenches are suitable for various bolt removal or tightening applications. If you want to buy a pneumatic torque wrench and want to find a reliable supplier, please contact us.