Different Types of Clamping Tools for Your Workshop

Different Types of Clamping Tools for Your Workshop

2023-06-20 08:51:54 By:Admin

![What Are The Different Types Of Vise [Vice] Tools?](https://openwrench.top/wp-content/uploads/2023/12/20231226014753-658a30c94dd8e.jpg)

1. Bench Vise: This is the most commonly used type of vise and is typically mounted on a workbench. It consists of two parallel jaws that can be tightened or released using a screw mechanism. Bench vises are versatile and can be used for a wide range of tasks, such as holding objects while sawing, drilling, filing, or assembling.

2. Pipe Vise: As the name suggests, pipe vises are specifically designed to hold pipes securely in place. These vises typically have curved jaws that can grip cylindrical objects, such as pipes or tubes, while you work on them. Pipe vises are often used by plumbers, electricians, and metalworkers.

3. Woodworking Vise: These vises are specifically designed for woodworking tasks. They usually have larger jaws that are wider and longer to provide a larger surface area for clamping wooden boards, planks, or other pieces of wood securely. Woodworking vises may have additional features like bench dog holes or a quick-release mechanism for easy adjustments.

4. Machinist Vise: Machinist vises, also known as engineer’s vises, are designed for precision work in metalworking tasks. They have jaws that are accurately machined to hold small metal workpieces securely. Machinist vises often feature a swivel base that allows for 360-degree rotation, enabling versatile positioning of the workpiece.

5. Drill Press Vise: This type of vise is specifically made for use with a drill press. It is designed to securely hold a workpiece while drilling holes or performing other repetitive tasks. Drill press vises often have a quick-release mechanism for easy adjustments and are generally more compact in size compared to other types.

6. Cross Slide Vise: Cross slide vises, sometimes called compound vises, provide both horizontal and vertical movement capabilities. These vises are commonly used in metalworking and machining operations to precisely position the workpiece and facilitate accurate drilling, milling, or shaping.

7. Pipe and Bench Combination Vise: This type of vise combines the functionality of a bench vise with a pipe vise. It allows you to securely hold both flat objects and pipes or tubes, eliminating the need for multiple vises. Pipe and bench combination vises are commonly found in fabrication shops and garages.

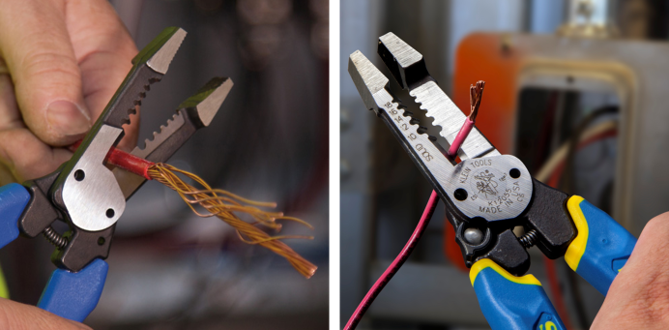

8. Hand Vise: Hand vises, also known as pin vises, are small, handheld tools used for delicate or intricate work. They typically consist of a handle with a collet or chuck at the end to grip small objects, such as wires, pins, or small diameter rods.

9. Vacuum Vise: Instead of a traditional screw or clamp mechanism, vacuum vises use suction to hold objects in place. These vises are often used for delicate and lightweight materials like electronic components or small plastic parts.

10. Magnetic Vise: As the name implies, magnetic vises use magnets to hold ferrous (magnetic) objects securely. They are commonly used in metalworking tasks such as welding or soldering, where clamping is required.

These are just a few examples of the different types of vise tools available. Each type has its own specific use case and features that make it suitable for different tasks. Choosing the right type of vise depends on your specific needs and the type of work you will be engaging in.